Injector

Function

An injector lifts and forces water into a boiler which is operating under pressure.

Construction

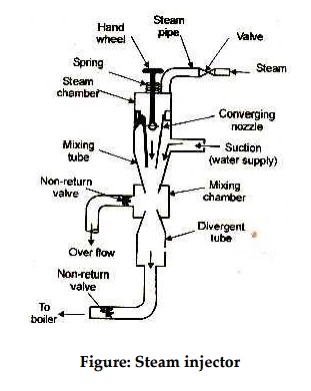

In consists of a converging nozzle, mixing chamber, divergent tube, steam valve and a non-return valve. A steam injector is shown in figure.

Working

The steam passes through the converging nozzle through a valve. Steam expands through the nozzle. The pressure drops and consequently velocity of steam increases. This steam mixes with water in the mixing chamber. In the mixing chamber steam condenses and vacuum is created. Due to this vacuum, more water is sucked into the mixing chamber. The jet water enters divergent tube. In the divergent tube kinetic energy of water is converted into pressure energy. Due to this increased pressure, feed water is forced into the boiler through feed check valve.

Figure: Steam injector

Application

They are commonly used in vertical and locomotive boilers.

Steam trap

Function

In any steam system, water may be formed due to partial condensation of steam in the piping system. This may cause water hammer and reduction in efficiency. A steam trap removes the condensed water, without allowing the steam to escape out.

Construction

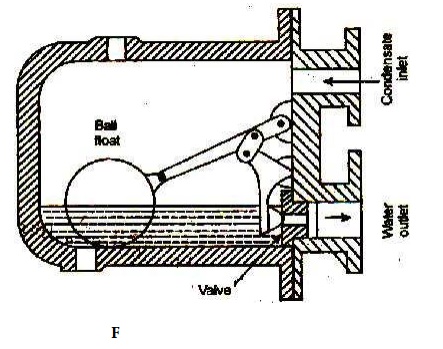

Figure: Ball float steam trap

Location

They are located on the steam mains, headers etc.

Working

The condensed water enters the steam trap by gravity. When the water level in the trap rises high enough, the ball float is lifted. This causes the valve to open and the water is discharged through the outlet. After the discharge of water, the float moves down. This causes the valve to close again.