Layout of Ash handling system

Ash Handling System:

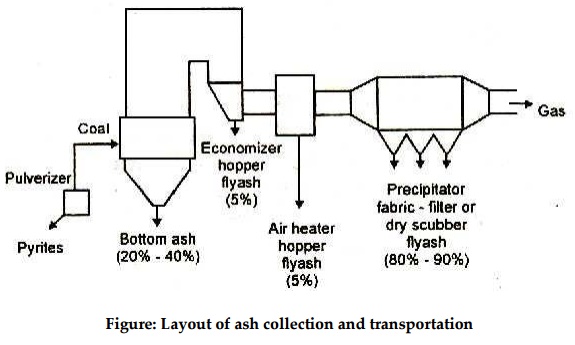

Boilers burning pulverized coal (PC) have bottom furnaces. The large ash particles are collected under the furnace in a water-filled ash hopper, Fly ash is collected in dust collectors with either an electrostatic precipitator or a baghouse. A PC boiler generates approximately 80% fly ash and 20% bottom ash. Ash must be collected and transported from various points of the plants as shown in figure. Pyrites, which are the rejects from the pulverizers, are disposed of with the bottom ash system. Three major factors should be considered for ash disposal systems.

1. Plant site

2. Fuel source

3. Environmental regulation

Needs for water and land are important considerations for many ash handling systems. Ash quantities to be disposed of depend on the king of fuel source. Ash storage and disposal sites are guided by environmental regulations.

Figure: Layout of ash collection and transportation

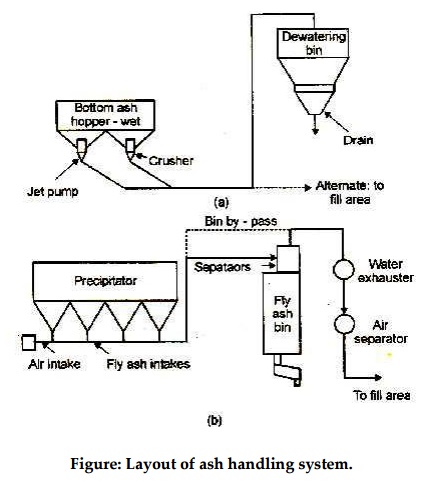

The sluice conveyor system is the most widely used for bottom ash handling, while the hydraulic vaccum conveyor (figure) is the most frequently used for fly systems.

Figure: Layout of ash handling system.

Bottom and slag may be used as filling material for road construction. Fly ash can partly replace cement for making concrete. Bricks can be made with fly ash. These are durable and strong.

Ash handling Equipment

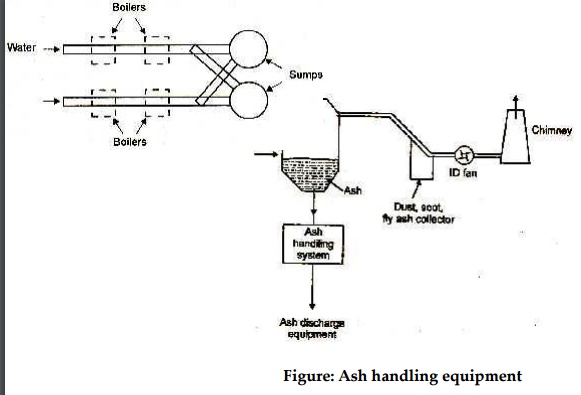

Ash Handling Equipment:

Mechanical means are required for the disposal of ash. The handling equipment should perform the following functions: 1. Capital investment, operating and maintenance charges of the equipment should be low. 2. It should be able to handle large quantities of ash. 3. Clinkers, shoot, dust etc. create troubles. The equipment should be able to handle them smoothly. 4. The equipment used should remove the ash from the furnace, load it to the conveying system to deliver the ash to dumping site or storage and finally it should have means to dispose of the stored ash. 5. The equipment should be corrosion and wear resistant.

Figure: Ash handling equipment