In order to understand the working of synchronous reluctance motor, when a piece of magnetic material is located in a magnetic field, a force acts on the material tending to bring it into the desert portion of the field. The force tends to align the specimen of the material in such a way that the reluctance of the magnetic path that passes through the material will be minimum.

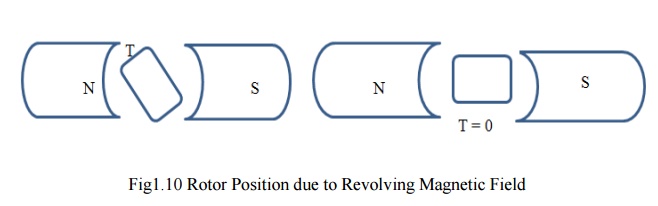

When supply is given to the stator winding, the revolving magnetic field will exert reluctance torque on the unsymmetrical rotor tending to align the salient pole axis of the rotor with the axis of the revolving magnetic field, because in this position, the reluctance of the magnetic path would be minimum. If the reluctance torque is sufficient to start the motor and its load, the rotor will pull into step with the revolving field and continue to run at the speed of the revolving field. Actually the motor starts as an induction motor and after it has reached its maximum speed as an induction motor, the reluctance torque pulls its rotor into step with the revolving field, motor now runs as synchronous motor by virtue of its saliency.

Reluctance motors have approximately one third the HP rating they would have as induction motors with cylindrical rotors. Although the ratio may be increased to 9one half by proper design of the field windings, power factor and efficiency are poorer than for the equivalent induction motor. Reluctance motors are subject to cogging, since the locked rotor torque varies with the rotor position, but the effect may be minimized by skewing the rotor bars and by not having the number of poles.