ROTOR CONSTRUCTION

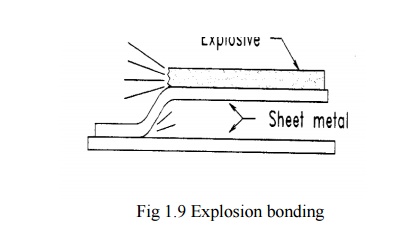

Explosion bonding technique as shown in fig. Other joining techniques such as brazing roll bonding, or diffusion bonding may also appropriate for rotor construction.

First sheets of ferromagnetic and non-ferromagnetic steel are bonded. The bonded sheets are then cut into rectangular blocks h\which are machined into the desired rotor. The rotor shaft can also be machined out of the same block as the rotor.

The rotor joining technique known as explosion bonding. Explosion bonding uses explosive energy to force two or more metal sheets together at high pressures. Conventionally the high pressure causes several atomic layers on the surface of each sheet to behave as a fluid. The angle of collision between the two metals forces this fluid to jet outward. Effectively cleaning the metal surface, these ultra clean surfaces along with the high pressure forcing the metal plates together provide the necessary condition for solid phase welding.

Experimental tests on a stainless steel/mild steel bond indicate that the tensile and fatigue strengths of the bond are greater than those of either of the component materials due to the shock hardening which occurs during the process. The bond was also subjected to 10 cycles of temperature variation from 20° C - 70°C, with no significant reduction in tensile strength.