The heat is removed by convection, conduction and radiation. Usually, the convection through air, liquid or steam is the most significant method of heat transfer. Forced convection is, inevitably, the most efficient cooling method if we do not take direct water cooling into account. The cooling design for forced convective cooling is also straightforward: the designer has to ensure that a large enough amount of coolant flows through the machine. This means that the cooling channels have to be large enough. If a machine with open-circuit cooling is of IP class higher than IP 20, using heat exchangers to cool the coolant may close the coolant flow.

If the motor is flange mounted, a notable amount of heat can be transferred through the flange of the machine to the device operated by the motor. The proportion of heat transfer by radiation is usually moderate, yet not completely insignificant. A black surface of the machine in particular promotes heat transfer by radiation.

Conduction

There are two mechanisms of heat transfer by conduction: first, heat can be transferred by molecular interaction, in which molecules at a higher energy level (at a higher temperature) release energy for adjacent molecules at a lower energy level via lattice vibration. Heat transfer of this kind is possible between solids, liquids and gases. The second means of conduction is heat transfer between free electrons. This is typical of liquids and pure metals in particular. The number of free electrons in alloys varies considerably, whereas in materials other than metals, the number of free electrons is small. The thermal conductivity of solids depends directly on the number of free electrons. Pure metals are the best heat conductors. Fourier’s law gives the heat flow transferred by conduction.

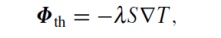

Where Φth is the heat flow rate, l the thermal conductivity, S the heat transfer area and ∇T the temperature gradient.