Specific Electrical and Magnetic loadings

Specific magnetic loading:

Following are the factors which influences the performance of the machine.

(i) Iron loss: A high value of flux density in the air gap leads to higher value of flux in the iron parts of the machine which results in increased iron losses and reduced efficiency.

(ii) Voltage: When the machine is designed for higher voltage space occupied by the insulation becomes more thus making the teeth smaller and hence higher flux density in teeth and core.

(iii) Transient short circuit current: A high value of gap density results in decrease in leakage reactance and hence increased value of armature current under short circuit conditions.

(iv) Stability: The maximum power output of a machine under steady state condition is indirectly proportional to synchronous reactance. If higher value of flux density is used it leads to smaller number of turns per phase in armature winding. This results in reduced value of leakage reactance and hence increased value of power and hence increased steady state stability.

(v) Parallel operation: The satisfactory parallel operation of synchronous generators depends on the synchronizing power. Higher the synchronizing power higher will be the ability of the machine to operate in synchronism. The synchronizing power is inversely proportional to the synchronous reactance and hence the machines designed with higher value air gap flux density will have better ability to operate in parallel with other machines.

Specific Electric Loading:

Following are the some of the factors which influence the choice of specific electric

loadings.

(i) Copper loss: Higher the value of q larger will be the number of armature of conductors which results in higher copper loss. This will result in higher temperature rise and reduction in efficiency.

(ii) Voltage: A higher value of q can be used for low voltage machines since the space required for the insulation will be smaller.

(iii) Synchronous reactance: High value of q leads to higher value of leakage reactance and armature reaction and hence higher value of synchronous reactance. Such machines will have poor voltage regulation, lower value of current under short circuit condition and low value of steady state stability limit and small value of synchronizing power.

(iv) Stray load losses: With increase of q stray load losses will increase. Values of specific magnetic and specific electric loading can be selected from Design Data Hand Book for salient and non salient pole machines.

Separation of D and L: Inner diameter and gross length of the stator can be calculated from D2L product obtained from the output equation. To separate suitable relations are assumed between D and L depending upon the type of the generator. Salient pole machines: In case of salient pole machines either round or rectangular pole construction is employed. In these types of machines the diameter of the machine will be quite larger than the axial length.

Thermal considerations

Classification of insulating materials based on thermal consideration

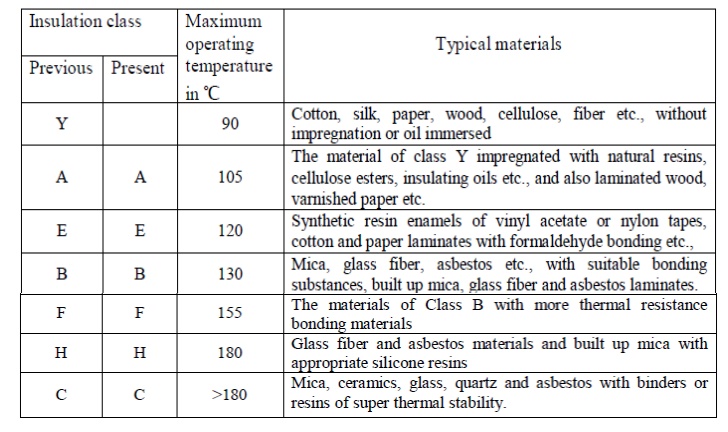

The insulation system (also called insulation class) for wires used in generators, motors transformers and other wire-wound electrical components is divided into different classes according the temperature that they can safely withstand.

As per Indian Standard (Thermal evaluation and classification of Electrical Insulation,IS.No.1271,1985,first revision) and other international standard insulation is classified by letter grades A,E,B,F,H (previous Y,A,E,B,F,H,C).

The maximum operating temperature is the temperature the insulation can reach during operation and

is the sum of standardized ambient temperature i.e. 40 degree centigrade, permissible temperature rise and allowance tolerance for hot spot in winding. For example, the maximum temperature of class B insulation is (ambient temperature 40 + allowable temperature rise 80 + hot spot tolerance 10) = 130oC.

Insulation is the weakest element against heat and is a critical factor in deciding the life of electrical equipment. The maximum operating temperatures prescribed for different class of insulation are for a healthy lifetime of 20,000 hours. The height temperature permitted for the machine parts is usually about 2000C at the maximum. Exceeding the maximum operating temperature will affect the life of the insulation. As a rule of thumb, the lifetime of the winding insulation will be reduced by half for every 10 ºC rise in temperature. The present day trend is to design the machine using class F insulation for class B temperature rise.