Working of gas turbine cycle with regenerator.

In earlier discussion it is seen that for the maximization of specific work output the gas turbine exhaust temperature should be equal to compressor exhaust temperature. The turbine exhaust temperature is normally much above the ambient temperature. Thus their exist potential for tapping the heat energy getting lost to surroundings with exhaust gases. Here it is devised to use this potential by means of a heat exchanger called regenerator, which shall preheat the air leaving compressor before entering the combustion chamber, thereby reducing the amount of fuel to be burnt inside combustion chamber (combustor).

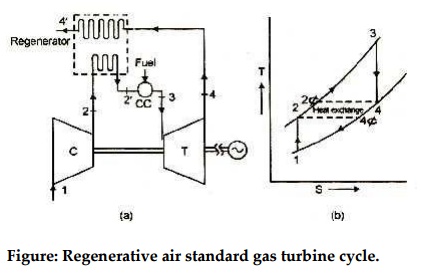

Regenerative air standard gas turbine cycles shown ahead in figure (a) has a regenerator (counter flow heat exchanger) through which the hot turbine exhaust gas and comparatively cooler air coming from compressor flow in opposite directions. Under ideal conditions, no frictional pressure drop occurs in either fluid stream while turbine exhaust gas gets cooled from 4 to 4’while compressed air is heated from 2 to 2’. Assuming regenerator effectiveness as 100% the temperature rise from 2 –2’ andropfromd4 to 4’isshown on T-S diagram.

Figure: Regenerative air standard gas turbine cycle.

Thus thermodynamically the amount of heat now added shall be

Q add, regen = m(h3 –h2’)

Whereas without regenerator the heat added; Qadd = m(h3 –h2)

Here it is obvious that, Qadd, regen < Qadd’

This shows an obvious improvement in cycle thermal efficiency as every thing else remains same. Network produced per unit mass flow is not altered by the use of regenerator.

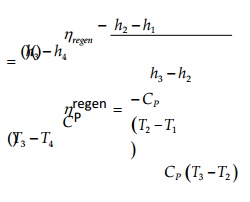

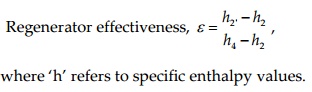

Air standard cycle thermal efficiency,