Layout of steam power plant:

Introduction:

Steam is an important medium for producing mechanical energy. Steam is used to drive steam engines and steam turbines. Steam has the following advantages.

1. Steam can be raised quickly from water which is available in plenty.

2. It does not react much with materials of the equipment used in power plants.

3. It is stable at temperatures required in the plant.

Equipment of a Steam Power Plant:

A steam power plant must have the following equipment.

1. A furnace for burning the fuel.

2. A steam generator or boiler for steam generation.

3. A power unit like an engine or turbine to convert heat energy into mechanical energy.

4. A generator to convert mechanical energy into electrical energy.

5. Piping system to carry steam and water.

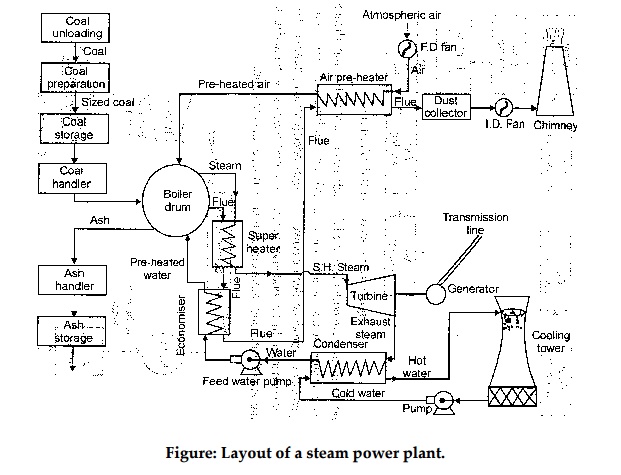

Figure: shows a schematic layout of a steam power plant. The working of a steam power plant can be explained in four circuits.

1. Fuel (coal) and ash circuit

2. Air and flue gas circuit

3. Feed water and steam flow circuit

4. Cooling water flow circuit

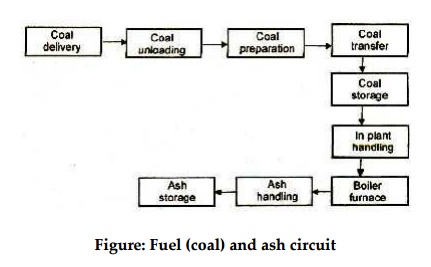

1. Coal and Ash circuit:

This includes coal delivery, preparation, coal handling, boiler furnace, ash handling and ash storage. The coal from coal mines is delivered by ships, rail or by trucks to the power station. This coal is sized by crushers, breakers etc. The sized coal is then stored in coal storage (stock yard). From the stock yard, the coal is transferred to the boiler furnace by means of conveyors, elevators etc.

The coal is burnt in the boiler furnace and ash is formed by burning of coal, Ash coming out of the furnace will be too hot, dusty and accompanied by some poisonous gases. The ash is transferred to ash storage. Usually, the ash is quenched to reduced temperature corrosion and dust content.

There are different methods employed for the disposal of ash. They are hydraulic system, water jetting, ash sluice ways, pneumatic system etc. In large power plants hydraulic system is used. In this system, ash falls from furnace grate into high velocity water stream. It is then carried to the slumps. A line diagram of coal and ash circuit is shown separately in figure.

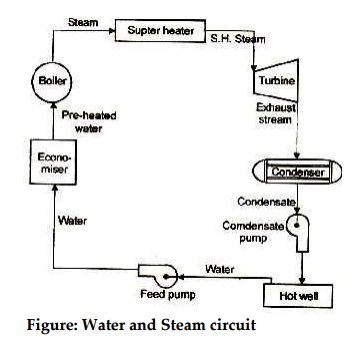

2. Water and Steam circuit

It consists of feed pump, economizer, boiler drum, super heater, turbine condenser etc.

Feed water is pumped to the economizer from the hot well. This water is preheated by the flue gases in the economizer. This preheated water is then supplied to the boiler drum. Heat is transferred to the water by the burning of coal. Due to this, water is converted into steam.

The steam raised in boiler is passed through a super heater. It is superheated by the flue gases. The superheated steam is then expanded in a turbine to do work. The turbine drives a generator to produce electric power. The expanded (exhaust) steam is then passed through the condenser. In the condenser, the steam is condensed into water and recirculated. A line diagram of water and steam circuit is shown separately in figure.

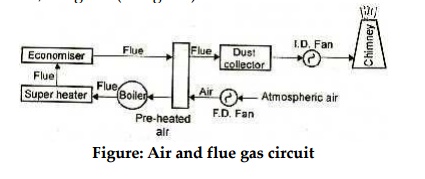

3. Air and Flue gas circuit

It consists of forced draught fan, air pre heater, boiler furnace, super heater, economizer, dust collector, induced draught fan, chimney etc. Air is taken from the atmosphere by the action of a forced draught fan. It is passed through an air pre-heater. The air is pre-heated by the flue gases in the pre-heater. This pre-heated air is supplied to the furnace to aid the combustion of fuel. Due to combustion of fuel, hot gases (flue gases) are formed.

Figure: Air and flue gas circuit

The flue gases from the furnace pass over boiler tubes and super heater tubes. (In boiler, wet steam is generated and in super heater the wet steam is superheated by the flue gases.) Then the flue gases pass through economizer to heat the feed water. After that, it passes through the air pre-heater to pre-heat the incoming air. It is then passed through a dust catching device (dust collector). Finally, it is exhausted to the atmosphere through chimney. A line diagram of air and flue gas circuit is shown separately in figure.

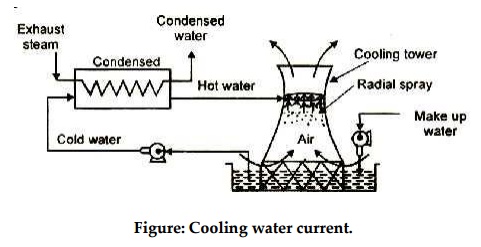

4. Cooling water circuit:

The circuit includes a pump, condenser, cooling tower etc. the exhaust steam from the turbine is condensed in condenser. In the condenser, cold water is circulated to condense the steam into water. The steam is condensed by losing its latent heat to the circulating cold water.

Figure: Cooling water current.

Thus the circulating water is heated. This hot water is then taken to a cooling tower, In cooling tower, the water is sprayed in the form of droplets through nozzles. The atmospheric air enters the cooling tower from the openings provided at the bottom of the tower. This air removes heat from water. Cooled water is collected in a pond (known as cooling pond). This cold water is again circulated through the pump, condenser and cooling tower. Thus the cycle is repeated again and again. Some amount of water may be lost during the circulation due to vaporization etc. Hence, make up water is added to the pond by means of a pump. This water is obtained from a river or lake. A line diagram of cooling water circuit is shown in figure separately.

Merits (Advantages) of a Thermal Power Plant

1. The unit capacity of a thermal power plant is more. The cost of unit decreases with the increase in unit capacity.

2. Life of the plant is more (25-30 years) as compared to diesel plant (2-5 years).

3. Repair and maintenance cost is low when compared with diesel plant.

4. Initial cost of the plant is less than nuclear plants.

5. Suitable for varying load conditions.

6. No harmful radioactive wastes are produced as in the case of nuclear plant.

7. Unskilled operators can operate the plant.

8. The power generation does not depend on water storage.

9. There are no transmission losses since they are located near load centres.

Demerits of thermal power plants

1. Thermal plant are less efficient than diesel plants

2. Starting up the plant and bringing into service takes more time.

3. Cooling water required is more.

4. Space required is more

5. Storage required for the fuel is more

6. Ash handling is a big problem.

7. Not economical in areas which are remote from coal fields

8. Fuel transportation, handling and storage charges are more

9. Number of persons for operating the plant is more than that of nuclear plants. This increases operation cost.

10. For large units, the capital cost is more. Initial expenditure on structural materials, piping, storage mechanisms is more.