Working principle of Economizer

Boiler Accessories:

Economizer:

Function:

An economizer pre –heats (raise the temperature) the feed water by the exhaust flue gases. This pre –heated water is supplied to the boiler from the economizer.

Location:

An economizer is placed in the path of the flue gases in between the boiler and the air pre – heater or chimney.

Construction:

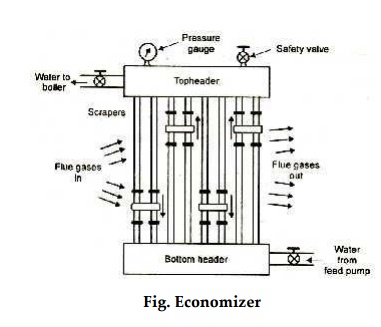

An economizer used in modern high pressure boilers is shown by a line sketch. It consists of a series of vertical tubes. These tubes are hydraulically pressed into the top and bottom headers. The bottom header is connected to feed pump. Top header is connected to the water space of the boiler. It is provided with a safety valve which opens when water pressure exceeds a certain limit. To keep the surface of the tubes clean from soot and ash deposits, scrapers are provided in the tubes. These scrapers are slowly moved up and down to clean the surfaces of the tubes. The action of adjacent pairs of scraper is in opposite direction. i.e., when one scraper moves up, the other moves down.

Economizers may be parallel or counter-flow types. When the gas flow and water flow are in the same direction, it is called parallel flow economizer. In counter-flow, the gas flow and water flow are in opposite direction.

Fig. Economizer

Working

The feed water is pumped to the bottom header and this water is carried to the top header through a number of vertical tubes. Hot flue gases are allowed to pass over the external surface of the tubes. The feed water which flows upward in the tubes is thus heated by the flue gases. This pre-heated water is supplied to the boiler.

Advantages

1. Feed water to the boiler is supplied at high temperature. Hence heat required in the boiler is less. Thus fuel consumption is less.

2. Thermal efficiency of the plant is increased.

3. Life of boiler is increased.

4. Loss of heat in flue gases is reduced.

5. Steaming capacity is increased.