1.Bubbling fluidized bed combustor,

2. Circulating fluidized bed combustor

Bubbling fluidized bed combustor

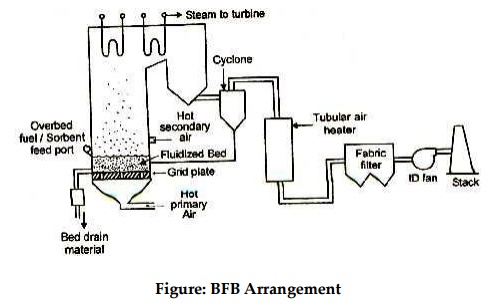

A typical BFB arrangement is illustrated schematically in figure. Fuel and sorbent are introduced either above or below the fluidized bed. (Overbed feed is illustrated.) The bed consisting of about 97% limestone or inert material and 3% burning fuel, is suspended by hot primary air entering the bottom of the combustion chamber. The bed temperature is controlled by heat transfer tubes immersed in the bed and by varying the quantity of coal in the bed. As the coal particle size decreases, as a result of either combustion or attrition, the particles are elutriated from the bed and carried out the combustor. A portion of the particles elutriated from the bed are collected by a cyclone (or multiclone) collector down-stream of the convection pass and returned to the bed to improve combustion efficiency.

Figure: BFB Arrangement

Secondary air can be added above the bed to improve combustion efficiency and to achieve staged combustion , thus lowering NOx emissions. Most of the early BFBs used tubular air heaters to minimize air leakage that could occur as a result of relatively high primary air pressures required to suspend the bed. Recent designs have included regenerative type air heaters.

Circulating fluidized bed combustor

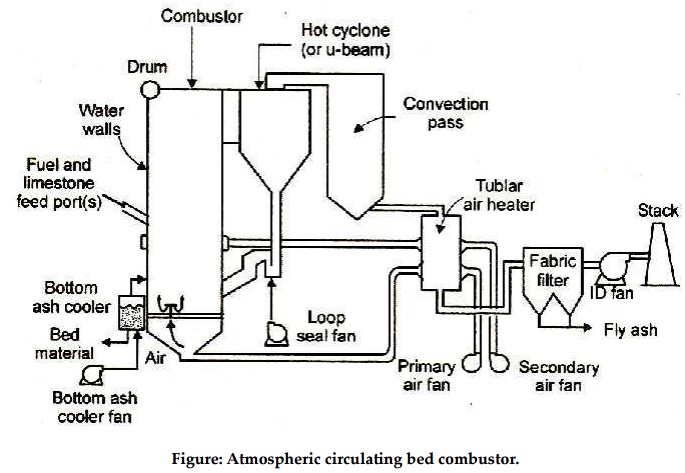

A typical CFB arrangement is illustrated schematically in figure. In a CFB, primary air is introduced into the lower portion of the combustor, where the heavy bed material is fluidized and retained. The upper portion of the combustor contains the less dense material that is entrained from the bed. Secondary air typically is introduced at higher levels in the combustor to ensure complete combustion and to reduce NOx emissions.

The combustion gas generated in the combustor flows upward with a considerable portion of the solids inventory entrained. These entrained solids are separated from the combustion gas in hot cyclone-type dust collectors or in mechanical particle separators, and are continuously returned to the combustion chamber by a recycle loop.

The combustion chamber of a CFB unit for utility applications generally consists of membrane-type welded water walls to provide most of the evaporative boiler surface. The lower third of the combustor is refractory lined to protect the water walls from erosion in the high-velocity dense bed region. Several CFB design offer external heat exchangers, which are unfired dense BFB units that extract heat from the solids collected by the dust collectors before it is returned to the combustor. The external heat exchangers are used to provide additional evaporative heat transfer surface as well as superheat and reheat surface, depending on the manufacturer’s design.

Figure: Atmospheric circulating bed combustor.

The flue gas, after removal of more than 99% of the entrained solids in the cyclone or particle separator, exists the cyclone or separator to a convection pass. The convection pass designs are similar to those used with unconventional coal-fueled units, and contain economizer, superheat, and reheat surface as required by the application.