Fuel Handling System

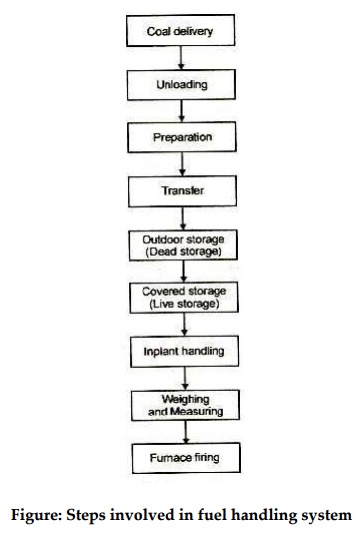

Coal delivery equipment is one of the major components of plant cost. The various steps involved in coal handling are as follows:

1. Coal delivery.

2. Unloading

3. Preparation

4. Transfer

5. Outdoor storage

6. Covered storage

7. Inplant handling

8. Weighing and measuring

9. Feeding the coal into furnace.

Figure: Steps involved in fuel handling system

i) Coal delivery

The coal from supply points is delivered by ships or boats to power stations situated near to sea or river whereas coal is supplied by rail or trucks to the power stations which are situated away from sea or river. The transportation of coal by trucks is used if the railway facilities are not available.

ii) Unloading

The type of equipment to be used for unloading the coal received at the power station depends on how coal is received at the power station. If coal delivered by trucks, there is no need of unloading device as the trucks may dump the coal to the outdoor storage. Coal is easily handled if the lift trucks with scoop are used. In case the coal is brought by railways wagons, ships or boats, the unloading may be done by car shakes, rotary car dumpers, cranes, grab buckets and coal accelerators. Rotary car dumpers although costly are quite efficient for unloading closed wagons.

(iii) Preparation

When the coal delivered is in the form of big lumps and it is not of proper size, the preparation (sizing) of coal can be achieved by crushers, breakers, sizers, driers and magnetic separators.

iv)Transfer

After preparation coal is transferred to the dead storage by means of the following systems.

1. Belt conveyors

2. Screw conveyors

3. Bucket elevators

4. Grab bucket elevators

5. Skip hoists

6. Flight conveyor