SYNCHRONOUS MACHINES

Introduction

Synchronous machines are AC machines that have a field circuit supplied by an external DC source. Synchronous machines are having two major parts namely stationary part stator and a rotating field system called rotor. In a synchronous generator, a DC current is applied to the rotor winding producing a rotor magnetic field. The rotor is then driven by external means producing a rotating magnetic field, which induces a 3-phase voltage within the stator winding. Field windings are the windings producing the main magnetic field (rotor windings for synchronous machines); armature windings are the windings where the main voltage is induced (stator windings for synchronous machines).

Types of synchronous machines

1. Hydrogenators : The generators which are driven by hydraulic turbines are called hydrogenators. These are run at lower speeds less than 1000 rpm.

2. Turbo generators: These are the generators driven by steam turbines. These generators are run at very high speed of 1500rpm or above.

3. Engine driven Generators: These are driven by IC engines. These are run at aspeed less than 1500 rpm. Hence the prime movers for the synchronous generators are Hydraulic turbines, Steam turbines or IC engines

Hydraulic Turbines: Pelton wheel Turbines: Water head 400 m and above Francis turbines: Water heads up to 380 m

Keplan Turbines: Water heads up to 50 m

Steam turbines: The synchronous generators run by steam turbines are called turbogenerators or turbo alternators. Steam turbines are to be run at very high speed to get higher efficiency and hence these types of generators are run at higher speeds.

Diesel Engines: IC engines are used as prime movers for very small rated generators.

Construction of synchronous machines

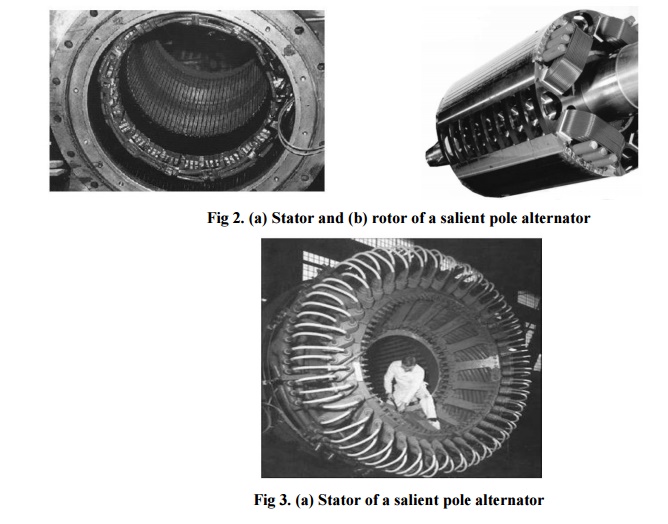

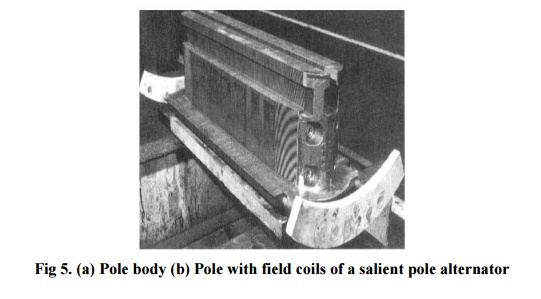

Salient pole Machines: These type of machines have salient pole or projecting poles with concentrated field windings. This type of construction is for the machines which are driven by hydraulic turbines or Diesel engines.

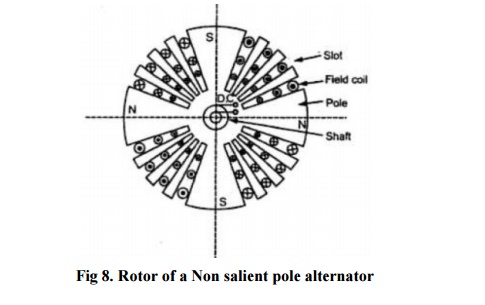

Non salient pole or Cylindrical rotor or Round rotor Machines: These machines are having cylindrical smooth rotor construction with distributed field winding in slots. This type of rotor construction is employed for the machine driven by steam turbines.

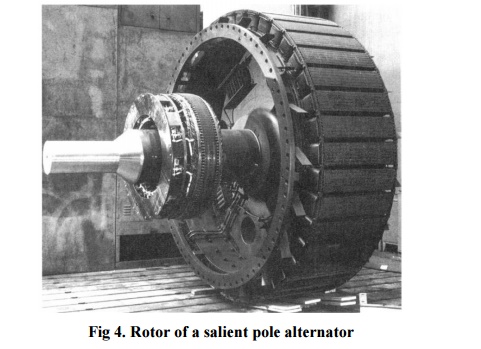

Construction of Hydro-generators: These types of machines are constructed based on the water head available and hence these machines are low speed machines. These machines are constructed based on the mechanical consideration. For the given frequency the low speed demands large number of poles and consequently largediameter. The machine should be so connected such that it permits the machine to be transported to the site. It is a normal to practice to design the rotor to withstand the centrifugal force and stress produced at twice the normal operating speed.

Stator core:

The stator is the outer stationary part of the machine, which consists of the outer cylindrical frame called yoke, which is made either of welded sheet steel, cast iron.

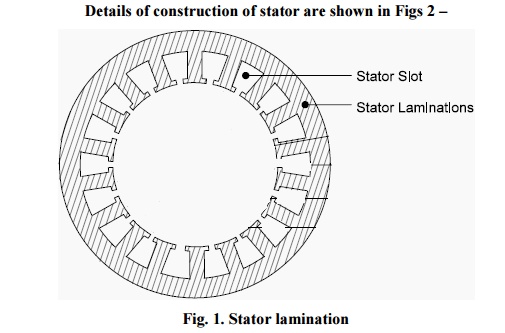

The magnetic path, which comprises a set of slotted steel laminations called stator core pressed into the cylindrical space inside the outer frame. The magnetic path is laminated to reduce eddy currents, reducing losses and heating. CRGO laminations of 0.5 mm thickness are used to reduce the iron losses.

A set of insulated electrical windings are placed inside the slots of the laminated stator. The cross-sectional area of these windings must be large enough for the power rating of the machine. For a 3-phase generator, 3 sets of windings are required, one for each phase connected in star. Fig. 1 shows one stator lamination of a synchronous generator.

In case of generators where the diameter is too large stator lamination can not be punched in on circular piece. In such cases the laminations are punched in segments. A number of segments are assembled together to form one circular laminations. All the laminations are insulated from each other by a thin layer of varnish.

Rotor of water wheel generator consists of salient poles. Poles are built with thin silicon steel laminations of 0.5mm to 0.8 mm thickness to reduce eddy current laminations. The laminations are clamped by heavy end plates and secured by studs or rivets. For low speed rotors poles have the bolted on construction for the machines with little higher peripheral speed poles have dove tailed construction as shown in Figs. Generally rectangular or round pole constructions are used for such type of alternators. However the round poles have the advantages over rectangular poles. Generators driven by water wheel turbines are of either horizontal or vertical shaft type. Generators with fairly higher speeds are built with horizontal shaft and the generators with higher power ratings and low speeds are built with vertical shaft design. Vertical shaft generators are of two types of designs (i) Umbrella type where in the bearing is mounted below the rotor. (ii) Suspended type where in the bearing is mounted above the rotor.