These are motors which are designed to be operated from single phase supply. They are widely use in watches and clocks, timers and counters. Present single phase stepping motors use one or more (two) permanent magnets, because permanent magnets are quite necessary to raise the ratio of torque to input power in a miniature motor.

The two requirements of single phase stepping motor are

To detent the motor at a particular position when the coil is not excited.

1. CONSTRUCTION

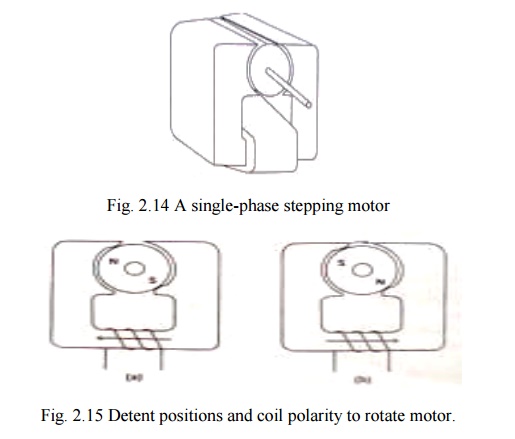

It is a permanent magnet type stepper motor with two poles. Rotor is a circular type of permanent magnet as shown in figure 2.27.ststor is made of silicon steel stampings with two salient poles. Stator carries a coil which is connected to a pulsed supply. The air gap is specially designed so that specific reluctance at different radial axes are different. Minimum values occur at one tip of the poles. Under normal conditions the rotor occupies any one of the decent position shown in fig 2.28(a0 or as in (b) to minimum reluctance position. two positions shown in figures 2.28(a) & (b) are the detent positions of the rotor of the stepper motor.

2. PRINCIPLE OF OPERATION

When the coil is given an electric positive pulse, pole A in position 1 as shown in figure. 2.28(a) it experiences a torque in clockwise direction and finally attains a steady state as in fig 2.28(b).then pulse given to the coil is zero. After a lapse of a second, from the start of the pulse, a negative pulse is given to the coil which makes the pole A as south and pole B as north. Rotor experiences another torque in figure 2.28(a).by repeating the cycle the rotor rotates continuously in step .it is not possible to develop torque in counter clockwise direction by altering pulses.