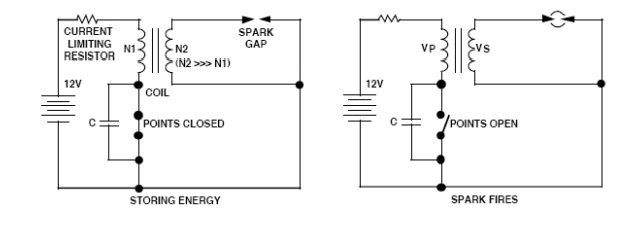

The "coil" used to generate the spark voltage is actually a transformer, with a very high secondary- to-primary turns ratio. When the points first close, current starts to flow in the primary winding and eventually reaches the final value set by the 12V battery and the current limiting resistor. At this time, the current flow is a fixed DC value, which means no voltage is generated across either winding of the transformer.

When the points open, the current in the primary winding collapses very quickly, causing a large voltage to appear across this winding. This voltage on the primary is magnetically coupled to (and stepped up by) the secondary winding, generating a voltage of 30 kV - 40 kV on the secondary side. As explained previously, the law of inductance says that it is not possible to instantly break the current flowing in an inductor (because an infinite voltage would be required to make it happen).

This principle is what causes the arcing across the contacts used in switches that are in circuits with highly inductive loads. When the switch just begins to open, the high voltage generated allows electrons to jump the air gap so that the current flow does not actually stop instantly. Placing a capacitor across the contacts helps to reduce this arcing effect. In the automobile ignition, a capacitor is placed across the points to minimize damage due to arcing when the points "break" the current flowing in the low-voltage coil winding (in car manuals, this capacitoris referred to as a "condenser").