Transformer is one of the most expensive and important equipment in power system. If it is not suitably designed its failure may cause a lengthy and costly outage. Therefore, it is very important to be cautious while designing its insulation, so that it can withstand transient over voltage both due to switching and lightning. The high voltage testing of transformers is, therefore, very important and would be discussed here. Other tests like temperature rise, short circuit, open circuit etc. are not considered here. However, these can be found in the relevant standard specification. Partial Discharge Test The test is carried out on the windings of the transformer to assess the magnitude of discharges. The transformer is connected as a test specimen similar to any other equipment as discussed in and the discharge measurements are made. The location and severity of fault is ascertained using the travelling wave theory technique as explained. The measurements are to be made at all the terminals of the transformer and it is estimated that if the apparent measured charge exceeds 104picocoulombs, the discharge magnitude is considered to be severe and the transformer insulation should be so designed that the discharge measurement should be much below the value of 104 Pico-coulombs.

Impulse Testing of Transformer

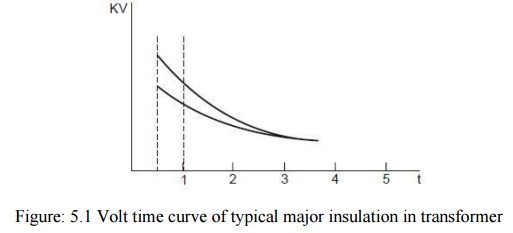

The impulse level of a transformer is determined by the breakdown voltage of its minor insulation (Insulation between turn and between windings), breakdown voltage of its major insulation (insulation between windings and tank) and the flash over voltage of its bushings or a combination of these. The impulse characteristics of internal insulation in a transformer differ from flash over in air in two main respects. Firstly the impulse ratio of the transformer insulation is higher (varies from 2.1 to 2.2) than that of bushing (1.5 for bushings, insulators etc.). Secondly, the impulse breakdown of transformer insulation in practically constant and is independent of time of application of impulse voltage.

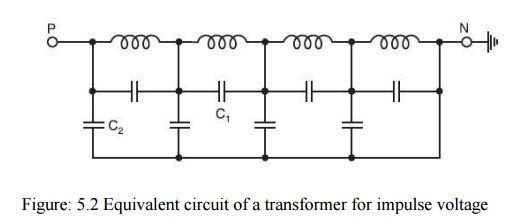

Fig.5.1 shows that after three micro seconds the flash over voltage is substantially constant. The voltage stress between the turns of the same winding and between different windings of the transformer depends upon the steepness of the surge wave front. The voltage stress may further get aggravated by the piling up action of the wave if the length of the surge wave is large. In fact, due to high steepness of the surge waves, the first few turns of the winding are overstressed and that is why the modern practice is to provide extra insulation to the first few turns of the winding. Fig. 5.2 shows the equivalent circuit of a transformer winding for impulse voltage.

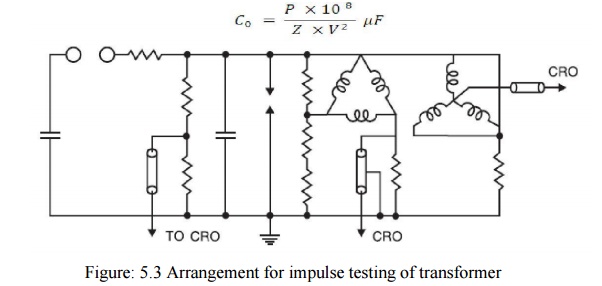

Here C1 represents inter-turn capacitance and C2 capacitance between winding and the ground (tank). In order that the minor insulation will be able to withstand the impulse voltage, the winding is subjected to chopped impulse wave of higher peak voltage than the full wave. This chopped wave is produced by flash over of a rod gap or bushing in parallel with the transformer insulation. The chopping time is usually 3 to 6 micro seconds. While impulse voltage is applied between one phase and ground, high voltages would be induced in the secondary of the transformer. To avoid this, the secondary windings are short-circuited and finally connected to ground. The short circuiting, however, decreases the impedance of the transformer and hence poses problem in adjusting the wave front and wave tail timings of wave. Also, the minimum value of the impulse capacitance required is given by

Where P = rated MVA of the transformer Z = per cent impedance of transformer. V = rated voltage of transformer. Fig. 5.3 shows the arrangement of the transformer for impulse testing. CRO forms an integral part of the transformer impulse testing circuit. It is required to record to wave forms of the applied voltage and current through the winding under test.

Impulse testing consists of the following steps:

i. Application of impulse of magnitude 75% of the Basic Impulse Level (BIL) of the transformer under test.

ii. One full wave of 100% of BIL.

iii. Two chopped wave of 115% of BIL.

iv. One full wave of 100% BIL and

v. One full wave of 75% of BIL.

During impulse testing the fault can be located by general observation like noise in the tank or smoke or bubble in the breather. If there is a fault, it appears on the Oscilloscope as a partial of complete collapse of the applied voltage. Study of the wave form of the neutral current also indicated the type of fault. If an arc occurs between the turns or form turn to the ground, a train of high frequency pulses are seen on the oscilloscope and wave shape of impulse changes. If it is a partial discharge only, high frequency oscillations are observed but no change in wave shape occurs. The bushing forms an important and integral part of transformer insulation. Therefore, its impulse flash over must be carefully investigated. The impulse strength of the transformer winding is same for either polarity of wave whereas the flash over voltage for bushing is different for different polarity. The manufacturer, however, while specifying the impulse strength of the transformer takes into consideration the overall impulse characteristic of the transformer.