Oil circuit breakers

Types Of Oil Circuit Breakers

Oil circuit breakers can be classified into following types:

1) Bulk oil circuit breakers

which use a large quantity of oil. In this circuit breaker the oil serves two purposes. Firstly it extinguishes the arc during opening of contacts and secondly it insulates the current conducting parts from one another and from the earthed tank. Such circuit breakers are classified into:

· Plain oil circuit breakers

· Arc control circuit breakers

In the former type no means is available for controlling the arc and the contacts are exposed to the whole of the oil in the tank. In the latter special arc control devices are employed to get the beneficial action of the arc as efficiently as possible

2) Low oil circuit breakers,

which use minimum amount of oil. In such circuit breakers oil is used only for arc extinction, the current conducting parts are insulated by air or porcelain or organic insulating material.

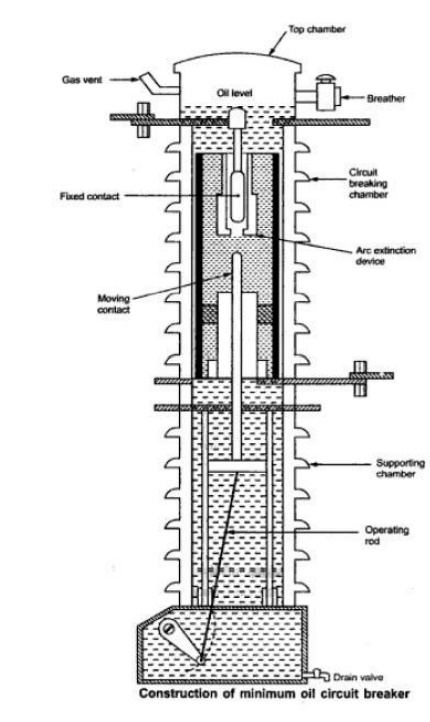

Construction

There are two chambers in a low oil circuit breaker; the oil in each chamber is separated from each other. The main advantage of this is that low oil is required and oil in second chamber won‘t get polluted. Upper chamber is called the circuit breaker chamber and lower one is called the supporting chamber. Circuit breaking chamber consists of moving contact and fixed contact.

Moving contact is connected with a piston it‘s just for the movement of the contact and no pressure build due to its motion. There are two vents on fixed contact they are axial vent for small current produced in oil due to heating of arc and radial vents for large currents. The whole device is covered using Bakelite paper and porcelain for protection. Vents are placed in a tabulator.

Operation

Under normal operating conditions, the moving contacts remain engaged with the upper fixed contact. When a fault occurs, the moving contact is pulled down by the tripping springs and an arc is struck. The arc vaporizes oil and produces gases under high pressure. This action constrains the oil to pass through a central hole in the moving contact and results in forcing series of oil through the respective passages of the turbulator.The process of tabulation is orderly one, in which the sections of arc are successively quenched by the effect of separate streams of oil, moving across each section in turn and bearing away its gases

constrains the oil to pass through a central hole in the moving contact and results in forcing series of oil through the respective passages of the turbulator.The process of tabulation is orderly one, in which the sections of arc are successively quenched by the effect of separate streams of oil, moving across each section in turn and bearing away its gases

Advantages

A low oil circuit breaker has following advantages compared to bulk oil circuit breaker

· It requires lesser quantity of oil

· It requires smaller space

· There is reduced risk of fire

· Maintenance problems are reduced

Disadvantages

· Low oil circuit breaker has following disadvantages compared to bulk oil circuit breaker

· Due to smaller quantity of oil, the degree of carbonization is increased

· There is a difficulty of removing the gases from the contact space in time