Construction and working principle of Boiling Water Reactor (BWR)

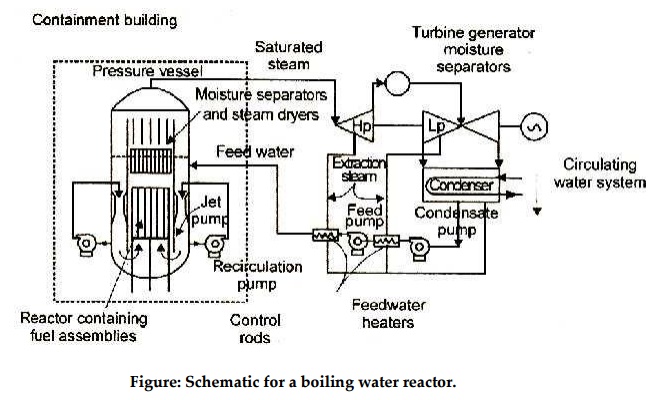

Figure shows a simplified BWR. Light water, which acts as the coolant and moderator, passes through the core where boiling takes place in the upper part of the core. The wet steam then passes through a bank of moisture separators and steam dryers in the upper part of the pressure vessel. The water that is not vaporized to steam is recirculated through the core with the entering feed water using two recirculation pumps coupled to jet pumps (usually 10 to 12 per recirculation pump). The steam leaving the top of the pressure vessel is at saturated conditions of 7.2 MPa and 278°C

The steam then expands through a turbine coupled to an electrical generator. After condensing to liquid in the condenser, the liquid is returned to the reactors as feedwater. Prior to entering the reactor, the feedwater is preheated in several stages of feedwater heaters. The balance of plant systems (Example: Turbine generator, feedwater heaters) are similar for both PWR and BWRs.

Figure: Schematic for a boiling water reactor.

The BWR reactor core, like that in a PWR, consists of a large number of fuel rods housed in fuel assemblies in a nearly cylindrical arrangement. Each fuel assembly contains an 8×8 or 9×9 square array of 64 or 81 fuel rods (typically two of the fuel rods contain water rather than fuel) surrounded by a square Zircaloy channel box to ensure no coolant crossflow in the core. The fuell rods are similar to the PWR rods, although larger in diameter. Each fuel rod is a zirconium alloy-clad tube containing pellets of slightly enriched uranium dioxide (2% to 5% U-235) stacked end-to-end. The reactor is controlled by control rods housed in a cross-shaped, or cruciform, arrangement called a control element. The control elements enter from the bottom of the reactor and move in spaces between the fuel assemblies.

The BWR reactor core is housed in a pressure vessel that is larger than that of a PWR. A typical BWR pressure vessel, which also houses the reactor core, moisture separators, and steam dryers, has a diameter of 6.4 m, with a height of 22 m. Since a BWR operators at a nominal pressure of 6.9 MPa, its pressure vessel is thinner that that of a PWR.