DIESEL ENGINE POWER PLANT SYSTEMS

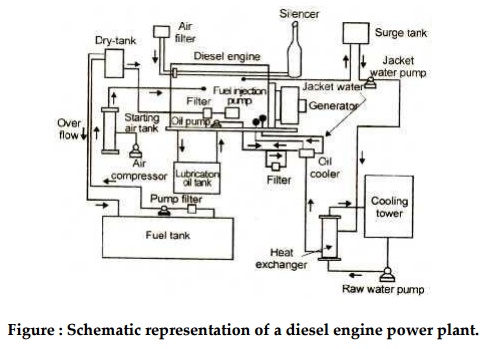

The diesel engine power plant consists of the following auxiliary systems:

Fuel Supply System

It consists of fuel tank for the storage of fuel, fuel filters and pumps to transfer and inject the fuel. The fuel oil may be supplied at the plant site by trucks, rail, road, tank, cars, etc.

Air Intake and Exhaust System

It consists of pipe for the supply of air and exhaust of the gases. Filters are provided to remove dust etc. from the incoming air. In the exhaust system silencer is provided to reduce the noise.

Filters may be of dry type (made up of cloth, felt, glass, wool etc.) or oil bath type. In oil bath type of filters the air is swept over or through a bath of oil in order that the particles of dust get coated. The duties of the air intake systems are as follows:

i) To clean the air intake supply.

ii) To silence the intake air.

iii) To supply air for super charging.

The intake system must cause a minimum pressure loss to avoid reducing engine capacity and raising the specific fuel consumption. Filters must be cleaned periodically to prevent pressure losses from clogging. Silencers must be used on some systems to reduce high velocity air noises.

3. Cooling Systems

This system provides a proper amount of water circulation all around the engines to keep the temperature at reasonable level. Pumps are used to discharge the water inside and the hot water leaving the jacket is cooled in cooling ponds or other devices and is recirculated again.

4. Lubrication System

Lubrication is essential to reduce friction and wear of the rubbing parts. It includes lubricating oil tank, pumps, filters and lubricating oil cooler.

Figure : Schematic representation of a diesel engine power plant.

5. Starting System

For the initial starting of engine the various devices used are compressed air, battery, electric motor or self-starter. The auxiliary equipment of diesel engine power plant.