Digital Transducers

A transducer measures physical quantities and transmits the information as coded digital signals rather than as continuously varying currents or voltages. Any transducer that presents information as discrete samples and that does not introduce a quantization error when the reading is represented in the digital form may be classified as a digital transducer. Most transducers used in digital systems are primarily analogue in nature and incorporate some form of conversion to provide the digital output. Many special techniques have been developed to avoid the necessity to use a conventional analogue - to-digital conversion technique to produce the digital signal. This article describes some of the direct methods which are in current use of producing digital outputs from transducers.

Some of the techniques used in transducers which are particularly adaptable for use in digital systems are introduced. The uses of encoder discs for absolute and incremental position measurement and to provide measurement of angul ar speed are outlined. The application of linear gratings for measurement of translational displacement is compared with the use of Moire fringe techniques used for similar purposes. Synchro devices are briefly explained and the various techniques used to produce a digital output from synchro resolvers are described. Brief descriptions of devices which develop a digital output from the natural frequency of vibration of some part of the transducer are presented. Digital techniques including vortex flowmeters and instruments using laser beams are also briefly dealt with. Some of them are as follows:

1. Shaft Encoders

2. Digital Resolvers

3. Digital Tachometers

4. Hall Effect Sensors

5. Limit Switches

Shaft Encoders:

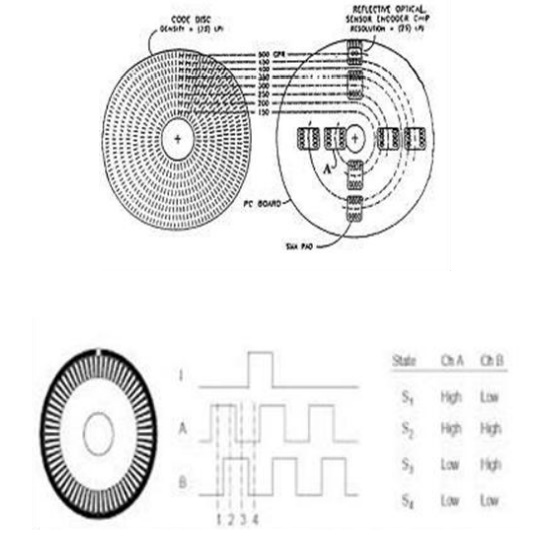

An encoder is a device that provides a coded reading of a measurement. A Shaft encoders can be one of the encoder that provide digital output measurements of angular position and velocity. This shaft encoders are excessively applicable in robotics, machine tools, mirror positioning systems, rotating machinery controls (fluid and electric), etc. Shaft encoders are basically of two types-Absolute and Incremental encoders.

An "absolute" encoder maintains position information when power is removed from the system. The position of the encoder is available immediately on applying power. The relationship between the encoder value and the physical position of the controlled machinery is set at assembly; the system does not need to return to a calibration point to maintain position accuracy. An "incremental" encoder accurately records changes in position, but does not power up with a fixed relation between encoder state and physical position. Devices controlled by incremental encoders may have to "go home" to a fixed reference point to initialize the position measurement. A multi-turn absolute rotary encoder includes additional code wheels and gears. A high-resolution wheel measures the fractional rotation, and lower-resolution geared code wheels record the number of whole revolutions of the shaft.

An absolute encoder has multiple code rings with various binary weightings which provide a data word representing the absolute position of the encoder within one revolution. This type of encoder is often referred to as a parallel absolute encoder.

An incremental encoder works differently by providing an A and a B pulse output that provide no usable count information in their own right. Rather, the counting is done in the external electronics. The point where the counting begins depends on the counter in the external electronics and not on the position of the encoder. To provide useful position information, the encoder position must be referenced to the device to which it is attached, generally using an index pulse. The distinguishing feature of the incremental encoder is that it reports an incremental change in position of the encoder to the counting electronics.