Voltage Control - Introduction

In a modern power system, electrical energy from the generating station is delivered to the ultimate consumers through a network of transmission and distribution. For satisfactory operation of motors, lamps and other loads, it is desirable that consumers are supplied with substantially constant voltage. Too wide variations of voltage may cause erratic operation or even malfunctioning of consumers’ appliances. To safe- guard the interest of the consumers, the government has enacted a law in this regard. The statutory limit of voltage variation is ± 6% of declared voltage at consumers’ terminals. The principal cause of voltage variation at consumer’s premises is the change in load on the supply system. When the load on the system increases, the voltage at the consumer’s terminals falls due to the increased voltage drop in

( i) alternator synchronous impedance

( ii) transmission line

( iii) transformer impedance

( iv) feeders and Condenser

(v) Distributors.

The reverse would happen should the load on the system decrease. These voltage variations are undesirable and must be kept within the prescribed limits ( i.e. ± 6% of the declared voltage). This is achieved by installing voltage regulating equipment at suitable places in the Voltage Control power system. The purpose of this chapter is to deal with important voltage control equipment and its increasing utility in this fast developing power system.

1. IMPORTANCE OF VOLTAGE CONTROL

When the load on the supply system changes, the voltage at the consumer’s terminals also changes.

The variations of voltage at the consumer’s terminals are undesirable and must be kept within prescribed limits for the following reasons :

( i) In case of lighting load, the lamp characteristics are very sensitive to changes of voltage.

For instance, if the supply voltage to an incandescent lamp decreases by 6% of rated value, then illuminating power may decrease by 20%. On the other hand, if the supply voltage is 6% above the rated value, the life of the lamp may be reduced by 50% due to rapid deterio-ration of the filament.

( ii) In case of power load consisting of induction motors, the voltage variations may cause erratic operation. If the supply voltage is above the normal, the motor may operate with a saturated magnetic circuit, with consequent large magnetising current, heating and low power factor. On the other hand, if the voltage is too low, it will reduce the starting torque of the motor considerably.

( iii) Too wide variations of voltage cause excessive heating of distribution transformers. This may reduce their ratings to a considerable extent.

It is clear from the above discussion that voltage variations in a power system must be kept to minimum level in order to deliver good service to the consumers. With the trend towards larger and larger interconnected system, it has become necessary to employ appropriate methods of voltage control.

2. LOCATION OF VOLTAGE CONTROL EQUIPMENT

In a modern power system, there are several elements between the generating station and the consumers. The voltage control equipment is used at more than one point in the system for two reasons.

Firstly, the power network is very extensive and there is a considerable voltage drop in transmission and distribution systems. Secondly, the various circuits of the power system have dissimilar load characteristics. For these reasons , it is necessary to provide individual means of voltage control for each circuit or group of circuits. In practice, voltage control equipment is used at :

( i) generating stations

( ii) transformer stations

(iii) the feeders if the drop exceeds the permissible limits 15.3 Methods of Voltage Control

There are several methods of voltage control. In each method, the system voltage is changed in accordance with the load to obtain a fairly constant voltage at the consumer’s end of the system. The following are the methods of voltage control in an *a.c. power system:

( i) By excitation control

( ii) By using tap changing transformers

( iii) Auto-transformer tap changing

( iv) Booster transformers

( v) Induction regulators

( vi) By synchronous condenser

Method ( i) is used at the generating station only whereas methods ( ii) to ( v) can be used for transmission as well as primary distribution systems. However, methods ( vi) is reserved for the voltage control of a transmission line. We shall discuss each method separately in the next sections.

1.Excitation Control

When the load on the supply system changes, the terminal voltage of the alternator also varies due to the changed voltage drop in the synchronous reactance of the armature. The voltage of the alternator can be kept constant by changing the *field current of the alternator in accordance with the load. This is known as excitation control method. The excitation of alternator can be controlled by the use of automatic or hand operated regulator acting in the field circuit of the alternator. The first method is preferred in modern practice. There are two main types of automatic voltage regulators viz.

( i) Tirril Regulator

( ii) Brown-Boveri Regulator

These regulators are based on the “overshooting the mark †principle” to enable them to respond quickly to the rapid fluctuations of load. When the load on the alternator increases, the regulator produces an increase in excitation more than is ultimately necessary. Before the voltage has the time to increase to the value corresponding to the increased excitation, the regulator reduces the excitation to the proper value.

i)Tirril Regulator

In this type of regulator, a fixed resistance is cut in and cut out of the exciter field circuit of the alternator. This is achieved by rapidly opening and closing a shunt circuit across the exciter rheostat.

For this reason, it is also known as vibrating type voltage regulator.

Construction

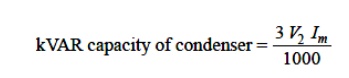

Fig. shows the essential parts of a Tirril voltage regulator. A rheostat R is provided in the exciter circuit and its value is set to give the required excitation. This rheostat is put in and out of the exciter circuit by the regulator, thus varying the exciter voltage to maintain the desired voltage of the alternator.

( i) Main contact.

There are two levers at the top which carry the main contacts at the facing ends. The left-hand lever is controlled by the exciter magnet whereas the right hand lever is controlled by an a.c. magnet known as main control magnet.

( ii) Exciter magnet.

This magnet is of the ordinary solenoid type and is connected across the exciter mains. Its exciting current is, therefore, proportional to the exciter voltage. The counter balancing force for the exciter magnet is provided by four coil springs.

( iii) A. C. magnet.

It is also of solenoid type and is energised from a.c. bus-bars. It carries series as well as shunt excitation. This magnet is so adjusted that with normal load and voltage at the alternator, the pulls of the two coils are equal and opposite, thus keeping the right-hand lever in the horizontal position.

( iv) Differential relay.

It essentially consists of a U-shaped relay magnet which operates the relay contacts. The relay magnet has two identical windings wound differentially on both the limbs. These windings are connected across the exciter mains–the left hand one permanently while the right hand one has its circuit completed only when the main contacts are closed. The relay contacts are arranged to shunt the exciter-field rheostat R. A capacitor is provided across the relay contacts to reduce the sparking at the time the relay contacts are opened.

Operation

The two control magnets ( i.e. exciter magnet and a.c. magnet) are so adjusted that with normal load and voltage at the alternator, their pulls are equal, thus keeping the main contacts open. In this position of main contacts, the relay magnet remains energised and pulls down the armature carrying one relay contact. Consequently, relay contacts remain open and the exciter field rheostat is in the field circuit.

When the load on the alternator increases, its terminal voltage tends to fall. This causes the series excitation to predominate and the a.c. magnet pulls down the right-hand lever to close the main contacts. Consequently, the relay magnet is *de-energised and releases the armature carrying the relay contact. The relay contacts are closed and the rheostat R in the field circuit is short circuited.

This increases the exciter-voltage and hence the excitation of the alternator. The increased excitation causes the alternator voltage to rise quickly. At the same time, the excitation of the exciter magnet is increased due to the increase in exciter voltage. Therefore, the left-hand lever is pulled down, opening the main contacts, energising the relay magnet and putting the rheostat R again in the field circuit before the alternator voltage has time to increase too far. The reverse would happen should the load on the alternator decrease.

It is worthwhile to mention here that exciter voltage is controlled by the rapid opening and closing of the relay contacts. As the regulator is worked on the overshooting the mark principle, therefore, the terminal voltage does not remain absolutely constant but oscillates between the maximum and minimum values. In fact, the regulator is so quick acting that voltage variations never exceed ± 1%.

ii)Brown-Boveri Regulator

In this type of regulator, exciter field rheostat is varied continuously or in small steps instead of being first completely cut in and then completely cut out as in Tirril regulator. For this purpose, a regulating resistance is connected in series with the field circuit of the exciter. Fluctuations in the alternator voltage are detected by a control device which actuates a motor. The motor drives the regulating rheostat and cuts out or cuts in some resistance from the rheostat, thus changing the exciter and hence the alternator voltage.

Construction

Fig. shows the schematic diagram of a Brown-Boveri voltage regulator. It also works on the “overshooting the mark principle” and has the following four important parts :

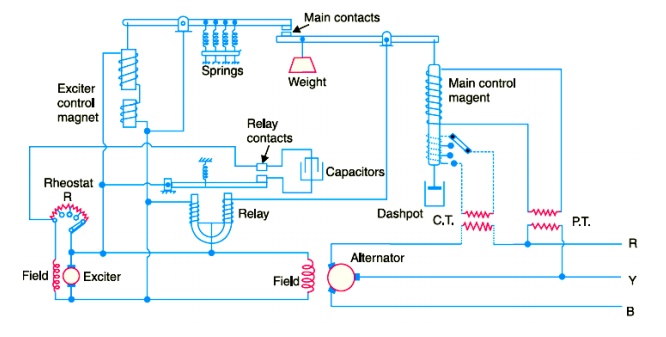

( i) Control system

The control system is built on the principle of induction motor. It consists of two windings A and B on an annular core of laminated sheet steel. The winding A is excited from two of the generator terminals through resistances U and U′ while a resistance R is inserted in the circuit of winding B. The ratio of resistance to reactance of the two windings are suitably adjusted so as to create a phase difference of currents in the two windings. Due to the phase difference of currents in the two windings, rotating magnetic field is set up. This produces electromagnetic torque on the thin aluminium drum C carried by steel spindle ; the latter being supported at both ends by jewel bearings. The torque on drum C varies with the terminal voltage of the alternator. The variable resistance U’ can also vary the torque on the drum.

If the resistance is increased, the torque is decreased and vice-versa. Therefore, the variable resistance U′ provides a means by which the regulator may be set to operate at the desired voltage.

( ii) Mechanical control torque

The electric torque produced by the current in the split phase winding is opposed by a combination of two springs (main spring and auxiliary spring) which produce a constant mechanical torque irrespective of the position of the drum. Under steady deflected state, mechanical torque is equal and opposite to the electric torque.

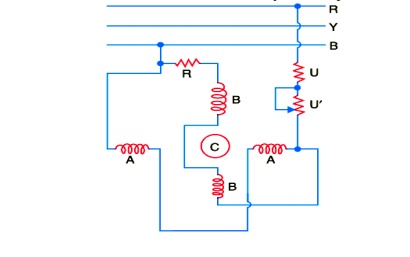

( iii) Operating system

It consists of a field rheostat with contact device. The rheostat consists of a pair of resistance elements connected to the stationary contact blocks CB . These two resistance sectors R are connected in series with each other and then in series with the field circuit of the exciter.

On the inside surface of the contact blocks roll the contact sectors Cs .

( iv) Damping torque

The regulator is made stable by damping mechanism which consists of an aluminium disc O rotating between two permanent magnets m. The disc is geared to the rack of an aluminium sector P and is fastened to the aluminium drum C by means of a flexible spring S acting as the recall spring. If there is a change in the alternator voltage, the eddy currents induced in the disc O produce the necessary damping torque to resist quick response of the moving system.

Operation

Suppose that resistances U and U′ are so adjusted that terminal voltage of the alternator is normal at position 1. In this position, the electrical torque is counterbalanced by the mechanical torque and the moving system is in equilibrium. It is assumed that electrical torque rotates the shaft in a clockwise direction.

Now imagine that the terminal voltage of the alternator rises due to decrease in load on the supply system. The increase in the alternator voltage will cause an increase in electrical torque which becomes greater than the mechanical torque. This causes the drum to rotate in clockwise direction, say to position 3. As a result, more resistance is inserted in the exciter circuit, thereby decreasing the field current and hence the terminal voltage of the alternator. Meanwhile, the recall spring S is tightened and provides a counter torque forcing the contact roller back to position 2 which is the equilibrium position. The damping system prevents the oscillations of the system about the equilibrium position.

2.Tap-Changing Transformers

The excitation control method is satisfactory only for relatively short lines. However, it is *not suitable for long lines as the voltage at the alternator terminals will have to be varied too much in order that the voltage at the far end of the line may be constant. Under such situations, the problem of voltage control can be solved by employing other methods. One important method is to use tap-changing transformer and is commonly employed where main transformer is necessary. In this method, a number of tappings are provided on the secondary of the transformer. The voltage drop in the line is supplied by changing the secondary e.m.f. of the transformer through the adjustment of its number of turns.

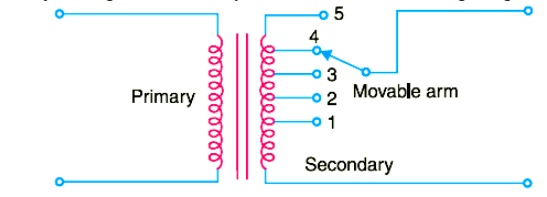

( i) Off load tap-changing transformer.

Fig. shows the arrangement where a number of tappings have been provided on the sec-ondary. As the position of the tap is varied, the effective number of secondary turns is varied and hence the output voltage of the secondary can be changed. Thus referring to Fig.

when the movable arm makes contact with stud 1, the secondary voltage is minimum and when with stud 5, it is maximum. During the period of light load, the voltage across the primary is not much below the alternator voltage and the movable arm is placed on stud 1. When the load increases, the voltage across the primary drops, but the secondary voltage can be kept at the previous value by placing the movable arm on to a higher stud. Whenever a tapping is to be changed in this type of transformer, the load is kept off and hence the name off load tap-changing transformer. The principal disadvantage of the circuit arrangement shown in Fig. is that it cannot be used for tap-changing on load. Suppose for a moment that tapping is changed from position 1 to position 2 when the transformer is supplying load. If contact with stud 1 is broken before contact with stud 2 is made, there is break in the circuit and arcing results. On the other hand, if contact with stud 2 is made before contact with stud 1 is broken, the coils connected between these two tappings are short-circuited and carry damaging heavy currents. For this reason, the above circuit arrangement cannot be used for tap-changing on load.

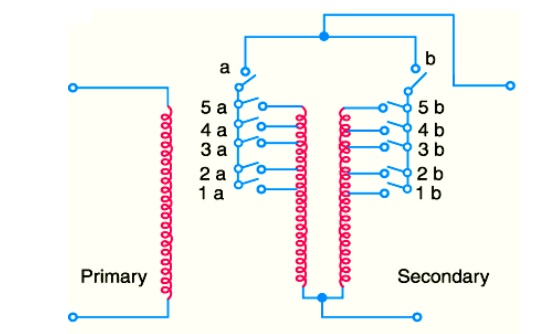

( ii) On-load tap-changing transformer

In supply system, tap-changing has normally to be performed on load so that there is no interruption to supply. Fig shows diagrammatically one type of on-load tap-changing transformer. The secondary consists of two equal parallel windings which have similar tappings 1 a ...... 5 a and 1 b ......... 5 b. In the normal working conditions, switches a, b and tappings with the same number remain closed and each secondary winding carries one-half of the total current. Referring to Fig.

the secondary voltage will be maximum when switches a, b and 5 a, 5 b are closed. However, the secondary voltage will be minimum when switches a, b and 1 a, 1 b are closed. Suppose that the transformer is working with tapping position at 4 a, 4 b and it is desired to alter its position to 5 a, 5 b. For this purpose, one of the switches a and b, say a, is opened. This takes the secondary winding controlled by switch a out of the circuit. Now, the secondary winding controlled by switch b carries the total current which is twice its rated capacity. Then the tapping on the disconnected winding is changed to 5 a and switch a is closed. After this, switch b is opened to disconnect its winding, tapping position on this winding is changed to 5 b and then switch b is closed. In this way, tapping position is changed without interrupting the supply.

This method has the following disadvantages:

( i) During switching, the impedance of transformer is increased and there will be a voltage surge.

( ii) There are twice as many tappings as the voltage steps.

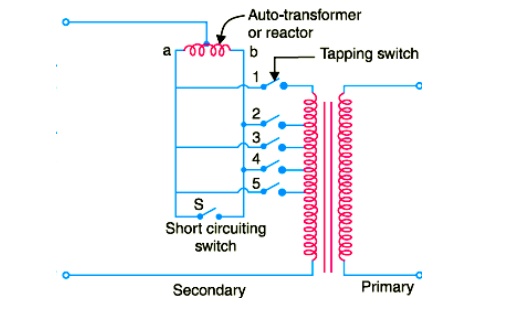

3.Auto-Transformer Tap-changing

Fig. shows diagrammatically auto-transformer tap changing. Here, a mid-tapped auto-transformer or reactor is used. One of the lines is connected to its mid-tapping. One end, say a of this transformer is connected to a series of switches across the odd tappings and the other end b is connected to switches across even tappings. A short-circuiting switch S is connected across the auto-transformer and remains in the closed position under normal operation. In the normal operation, there is *no inductive voltage drop across the auto-transformer. Referring to Fig, it is clear that with switch 5 closed, minimum secondary turns are in the circuit and hence the output voltage will be the lowest. On the other hand, the output voltage will be maximum when switch 1 is closed.

Suppose now it is desired to alter the tapping point from position 5 to position 4 in order to raise the output voltage. For this purpose, short-circuiting switch S is opened, switch 4 is closed, then switch 5 is opened and finally short-circuiting switch is closed. In this way, tapping can be changed without interrupting the supply.

It is worthwhile to describe the electrical phenomenon occurring during the tap changing. When the short-circuiting switch is opened, the load current flows through one-half of the reactor coil so that there is a voltage drop across the reactor. When switch 4 is closed, the turns between points 4 and 5 are connected through the whole reactor winding. A circulating current flows through this local circuit but it is limited to a low value due to high reactance of the reactor.

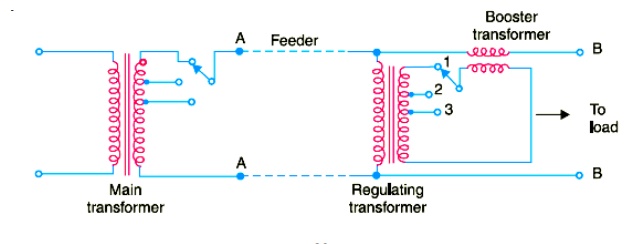

4.Booster Transformer

Sometimes it is desired to control the voltage of a transmission line at a point far away from the main transformer. This can be conveniently achieved by the use of a booster transformer as shown in Fig.

The secondary of the booster transformer is connected in series with the line whose voltage is to be controlled. The primary of this transformer is supplied from a regulating transformer *fitted with on-load tap-changing gear. The booster transformer is connected in such a way that its secondary injects a voltage in phase with the line voltage.

The voltage at AA is maintained constant by tap-changing gear in the main transformer. However, there may be considerable voltage drop between AA and BB due to fairly long feeder and tapping of loads. The voltage at BB is controlled by the use of regulating transformer and booster transformer. By changing the tapping on the regulating transformer, the magnitude of the voltage injected into the line can be varied. This permits to keep the voltage at BB to the de-sired value. This method of voltage control has three disadvantages. Firstly, it is more expensive than the on-load tap-changing transformer. Secondly, it is less efficient owing to losses in the booster and thirdly more floor space is required. Fig. shows a three-phase booster transformer.

6.Induction Regulators

An induction regulator is essentially a constant voltage transformer, one winding of which can be moved w.r.t. the other, thereby obtaining a variable secondary voltage. The primary winding is connected across the supply while the secondary winding is connected in series with the line whose voltage is to be controlled. When the position of one winding is changed w.r.t. the other, the secondary voltage injected into the line also changes. There are two types of induction regulators viz. single phase and 3-phase.

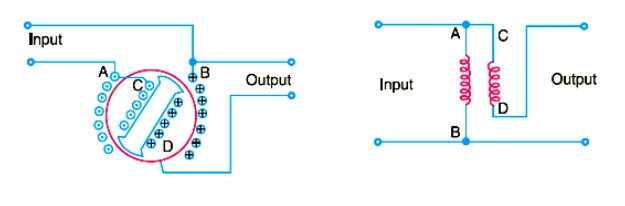

( i) Single-phase induction regulator.

A single phase induction regulator is illustrated in Fig. In construction, it is similar to a single phase induction motor except that the rotor is not allowed to rotate continuously but can be adjusted in any position either manually or by a small motor. The primary winding A B is wound on the *stator and is connected across the supply line. The secondary winding CD is wound on the rotor and is connected in series with the line whose voltage is to be controlled.

The primary exciting current produces an alternating flux that induces an alternating voltage in the secondary winding CD. The magnitude of voltage induced in the secondary depends upon its position w.r.t. the primary winding. By adjusting the rotor to a suitable position, the secondary voltage can be varied from a maximum positive to a maximum negative value. In this way, the regulator can add or subtract from the circuit voltage according to the relative positions of the two windings.

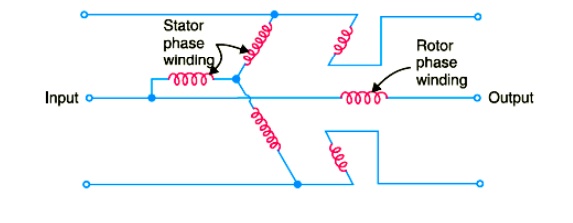

( ii) Three-phase induction regulator

In construction, a 3-phase induction regulator is similar to a 3-phase induction motor with wound rotor except that the rotor is not allowed to rotate continuously but can be held in any position by means of a worm gear. The primary windings either in star or delta are wound on the stator and are connected across the supply. The secondary windings are wound on the rotor and the six terminals are brought out since these windings are to be connected in series with the line whose voltage is to be controlled.

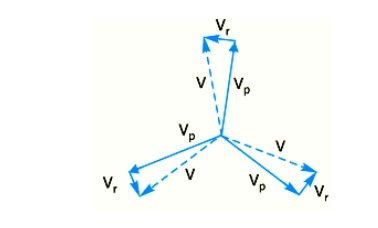

When poly phase currents flow through the primary windings, a rotating field is set up which induces an e.m.f. in each has of rotor winding. As the rotor is turned, the magnitude of the rotating flux is not changed; hence the rotor e.m.f. per phase remains constant. However, the variation of the position of the rotor will affect the phase of the rotor e.m.f. w.r.t. the applied voltage as shown in Fig.

The input primary voltage per phase is Vp and the boost introduced by the regulator is Vr . The output voltage V is the vector sum of Vp and Vr . Three phase p induction regulators are used to regulate the voltage of feeders and in connection with high voltage oil testing transformers.

6.Voltage Control by Synchronous Condenser

The voltage at the receiving end of a transmission line can be controlled by installing specially designed synchronous motors called *synchronous condensers at the receiving end of the line. The synchronous condenser supplies watt less leading kVA to the line depending upon the excitation of the motor. This watt less leading kVA partly or fully cancels the watt less lagging kVA of the line, thus controlling the voltage drop in the line. In this way, voltage at the receiving end of a transmission line can be kept constant as the load on the system changes.

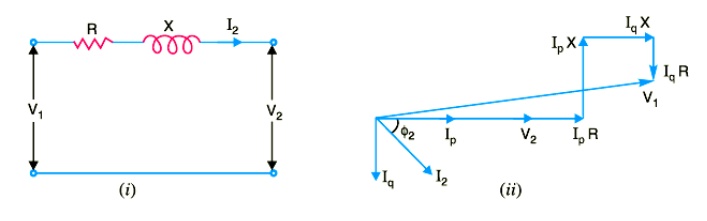

For simplicity, consider a short transmission line where the effects of capacitance are neglected. Therefore, the line has only resistance and inductance. Let V1 and V2 be the per phase sending end and receiving end voltages respectively. Let I2 be the load current at a lagging power factor of cos φ2 .

( i) Without synchronous condenser.

Fig. ( i) shows the transmission line with resistance R and inductive reactance X per phase. The load current I can be resolved into two 2 rectangular components viz I in phase with V and I at right angles to V Each component will produce resistive and reactive drops ; the resistive drops being in phase with and the reactive drops in quadrature leading with the corresponding currents. The vector addition of these voltage drops to V gives the sending end voltage V

( ii) With synchronous condenser

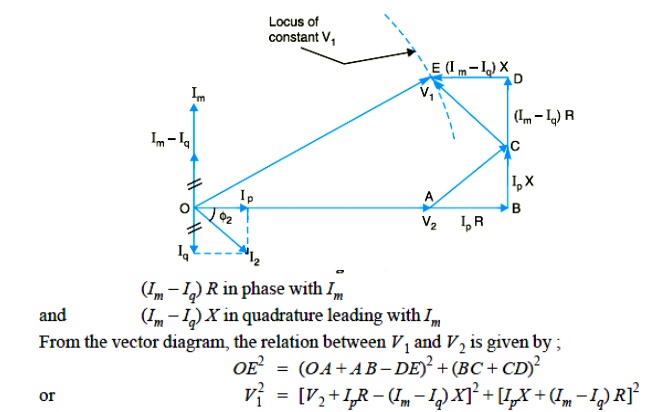

Now suppose that a synchronous condenser taking a leading current * *I is connected at the receiving end of the line. The vector diagram of the circuit becomes as shown in Fig. Note that since I and I are in direct opposition and that I must be greater than I , the four drops due to these two currents simplify to :

From this equation, the value of Im can be calculated to obtain any desired ratio of V1 / V2 for a