Electrodynamometer (Eelectrodynamic) Type Instruments: Operating Principle, Control, Torque Equation, Errors, Advantages and Disadvantages

Electrodynamometer (Eelectrodynamic) Type Instruments

The necessity for

the a.c. calibration of moving iron instruments as well as other types of instruments which cannot be correctly calibrated requires the use of a transfer type of instrument. A transfer instrument is one that may be calibrated with a d.c. source and then used without modification to measure a.c. This requires the transfer type instrument to have same accuracy for both d.c. and a.c., which the electrodynamometer instruments have.

These standards are precision resistors and the Weston standard cell (which is a d.c. cell).It is obvious, therefore, that it would be impossible to calibrate an a.c. instrument directly against the fundamental standards. The calibration of an a.c. instrument may be performed as follows. The transfer instrument is first calibrated on d.c. This calibration is then transferred to the a.c. instrument on alternating current, using operating conditions under which the latter operates properly. Electrodynamic instruments are capable of service as transfer instruments. Indeed, their principal use as ammeters and voltmeters in laboratory and measurement work is for the transfer calibration of working instruments and as standards for calibration of other nstruments as their accuracy is very high. Electrodynamometer types of instruments are used as a.c. voltmeters and ammeters both in the range of power frequencies and lower part of the audio power frequency range. They are used as watt-meters, and with some modification as power factor meters and frequency meters.

Operating Principle of Electrodynamometer Type Instrument

It would have a torque in one direction during one half of the cycle and an equal effect in the opposite direction during the other half of the cycle. If the frequency were very low, the pointer would swing back and forth around the zero point. However, for an ordinary meter, the inertia is so great that on power frequencies the pointer does not go very far in either direction but merely stays (vibrates slightly) around zero. If, however, we were to reverse the direction of the flux each time the current through the movable coil reverses, a unidirectional torque would be produced for both positive and negative halves of the cycle.

In electrodynamometer instruments the field can be made to reverse simultaneously with the current in the movable coil if the field (fixed) coil is connected in series with the movable coil.

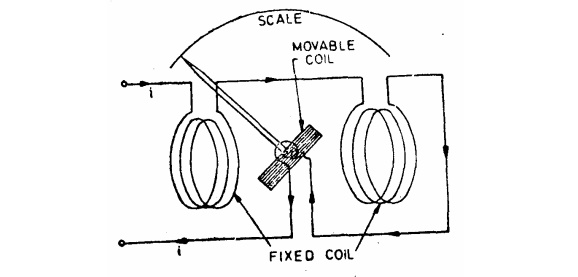

Construction of Electrodynamometer type instrument

Fixed Coils

The field is produced by a fixed coil.

This coil is divided into two sections to give a more uniform field near the centre and to allow passage of the instrument shaft.

Moving Coil

A single element instrument has one moving coil.

The moving coil is wound either as a self-sustaining coil or else on a non-metallic former.

A metallic former cannot be used as eddy current would be induced in it by the alternating field.

Light but rigid construction is used for the moving coil.

It should be noted that both fixed and moving coils are air cored.

Control

The controlling torque is provided by two control springs. These springs act as leads to the moving coil.

Moving System

The moving coil is mounted on an aluminum spindle.

The moving system also carries the counter weights and truss type pointer.

Sometimes a suspension may be used in case a high sensitivity is desired.

Damping

Air friction damping is employed for these instruments and is provided by a pair of aluminum vanes, attached to the spindle at the bottom.

These vanes move in sector shaped chambers.

Eddy current damping cannot be used in these instruments as the operating field is very weak (on account of the fact that the coils are air cored) and any introduction of a permanent magnet required for eddy current damping would distort the operating magnetic field of the instrument.

Shielding

The field produced by the fixed coils is somewhat weaker than in other types of instruments

It is nearly 0.005 to 0.006 Wb/m

In d.c. measurements even the earth magnetic field may affect the readings.

Thus it is necessary to shield an electrodynamometer type instrument from the effect of stray magnetic fields.

Air cored electrodynamometer type instruments are protected against external magnetic fields by enclosing them in a casing of high permeability alloy.

This shunts external magnetic fields around the instrument mechanism and minimizes their effects on the indication.

Cases and Scales

Laboratory standard instruments are usually contained in highly polished wooden cases.

These cases are so constructed as to remain dimensionally stable over long periods of time.

The glass is coated with some conducting material to completely remove the electrostatic effects.

The case is supported by adjustable leveling screws.

A spirit level is also provided to ensure proper leveling.

The scales are hand drawn, using machine sub-dividing equipment. Diagonal lines for fine sub-division are usually drawn for main markings on the scale.

Most of the high-precision instruments have a 300 mr scale with 100, 120 or 150 divisions.

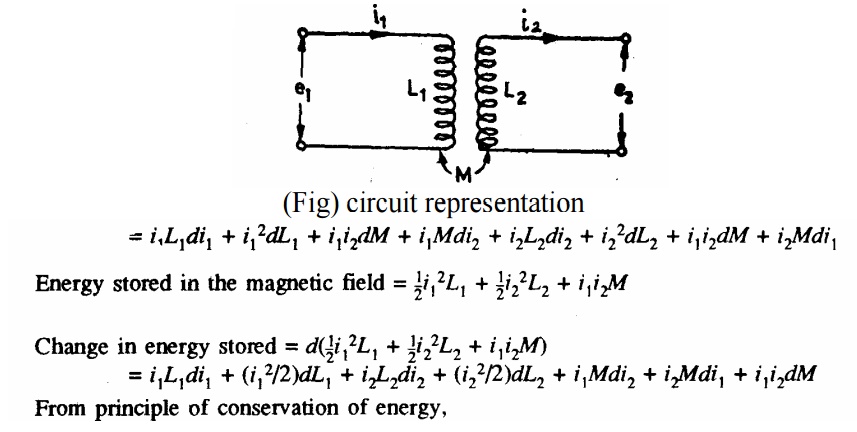

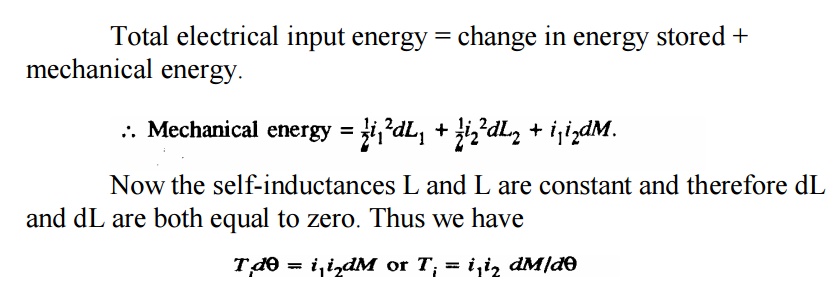

Torque Equation

Let i1 = instantaneous value of current in the fixed coils: A.

i2 = instantaneous value of current in the moving coil: A.

L1 = self-inductance of fixed coils: H.

L2 = self-inductance of moving coils H,

M = mutual inductance between fixed and moving coils: Flux linkages of coil 1, ȥ 1 = L1 i1 + Mi2

Flux linkages f coil 2, ȥ 2 = L2 i2 + Mi1

Electrical input energy = e1i1dt+e2i2dt

Errors in Electrodynamometer Instruments

i) Frequency error

ii) Eddy current error

iii) External magnetic field

iv) Temperature changes

Advantages

i) These instruments can be used on both a.c & d.c

ii) Accurate rms value

Disadvantages

(i) They have a low torque/weight ratio and hence have a low sensitivity.

(ii) Low torque/weight ratio gives increased frictional losses.

(iii) They are more expensive than either the PMMC or the moving iron type instruments.

(iv) These instruments are sensitive to overloads and mechanical impacts. Therefore, they must be handled with great care.

(v) The operating current of these instruments is large owing to the fact that they have weak magnetic field. The flux density is about 0.006 Wb/m as against 0.1 to 0.5 Wb/m in PMCC instruments

(vi) They have a non-uniform scale.