PID Controllers

Proportional controllers

– pure gain or attenuation

Integral controllers

– integrate error

Derivative controllers

– differentiate error

Proportional Controller

U = Kp e

o Controller input is error (reference output)

o Controller output is control signal

o P controller involves only a proportional gain (or attenuation)

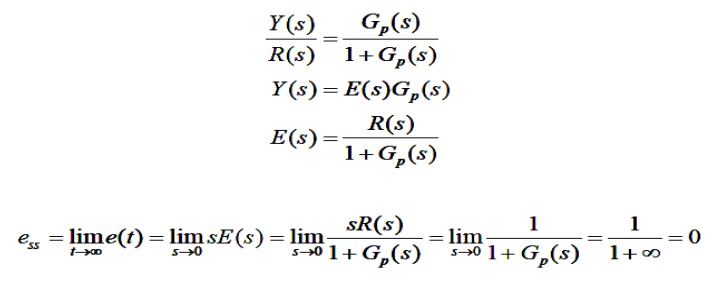

Integral Controller

o Integral of error with a constant gain

o Increase system type by 1

o Infinity steady-state gain

o Eliminate steady-state error for a unit step input

Integral Controller

Derivative Control

o Differentiation of error with a constant gain

o Reduce overshoot and oscillation

o Do not affect steady-state response

o Sensitive to noise

Controller Structure

o Single controller

o P controller, I controller, D controller

o Combination of controllers

o PI controller, PD controller

o PID controller

Controller Performance

o P controller

o PI controller

o PD Controller

o PID Controller

Design of PID Controllers

o Based on the knowledge of P, I and D

– trial and error

– manual tuning

– simulation

Design of PID Controllers

o Time response measurements are particularly simple.

o A step input to a system is simply a suddenly applied input - often just a constant voltage applied through a switch.

o The system output is usually a voltage, or a voltage output from a transducer measuring the output.

o A voltage output can usually be captured in a file using a C program or a Visual Basic program.

o You can use responses in the time domain to help you determine the transfer function of a system.

o First we will examine a simple situation. Here is the step response of a system. This is an example of really "clean" data, better than you might have from measurements. The input to the system is a step of height 0.4. The goal is to determine the transfer function of the system.