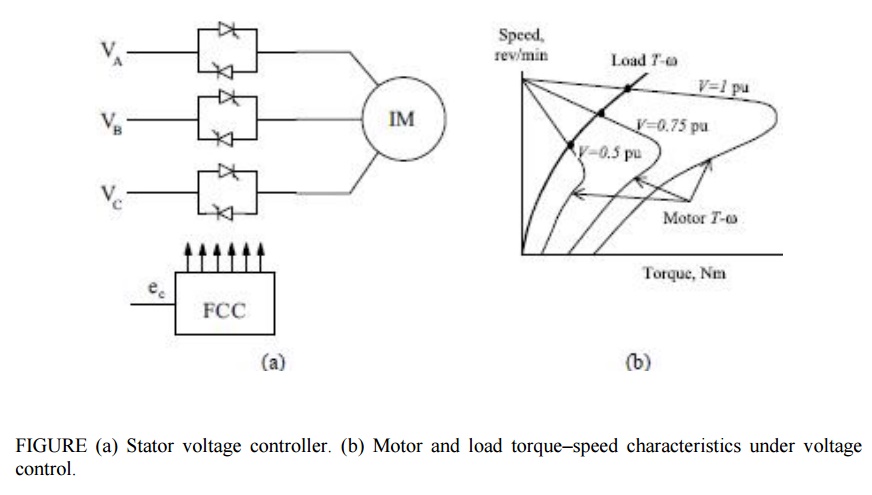

In this method of control, back-to-back thyristors are used to supply the motor with variable ac voltage. The analysis implies that the developed torque varies inversely as the square of the input RMS voltage to the motor. This makes such a drive suitable for fan- and impeller-type loads for which torque demand rises faster with speed. For other types of loads, the suitable speed range is very limited. Motors with high rotor resistance may offer an extended speed range. It should be noted that this type of drive with back-to-back thyristors with firing-angle control suffers from poor power and harmonic distortion factors when operated at low speed. If unbalanced operation is acceptable, the thyristors in one or two supply lines to the motor may be bypassed. This offers the possibility of dynamic braking or plugging, desirable in some applications.

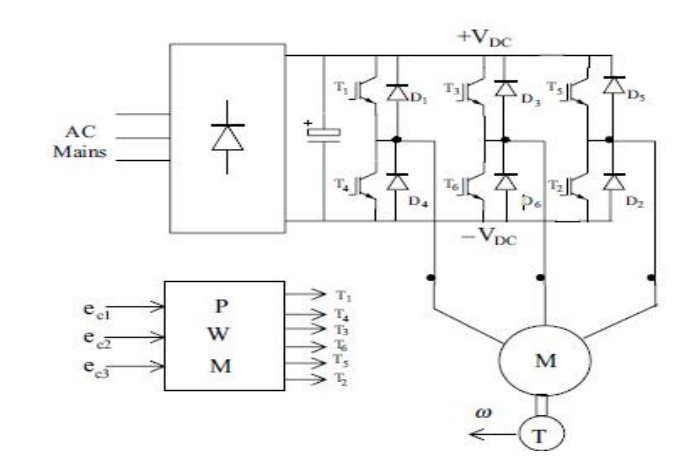

The induction motor speed variation can be easily achieved for a short range by either stator voltage control or rotor resistance control. But both of these schemes result in very low efficiencies at lower speeds. The most efficient scheme for speed control of induction motor is by varying supply frequency. This not only results in scheme with wide speed range but also improves the starting performance. If the machine is operating at speed below base speed, then v/f ratio is to be kept constant so that flux remains constant. This retains the torque capability of the machine at the same value. But at lower frequencies, the torque capability decrease and this drop in torque has to be compensated for increasing the applied voltage.