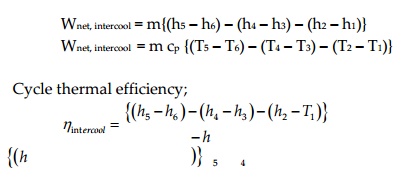

Net work output from gas turbine cycle can also be increased by reducing negative work i.e., compressor work. Multistaging of compression precess with intercooling in between is one of the approaches for reducing compression work. It is based on the fact that for a fixed compression ratio is higher is the inlet temperature higher shall be compression work requirement and vice-versa. Schematic for inter cooled gas turbine cycle is give in figure.

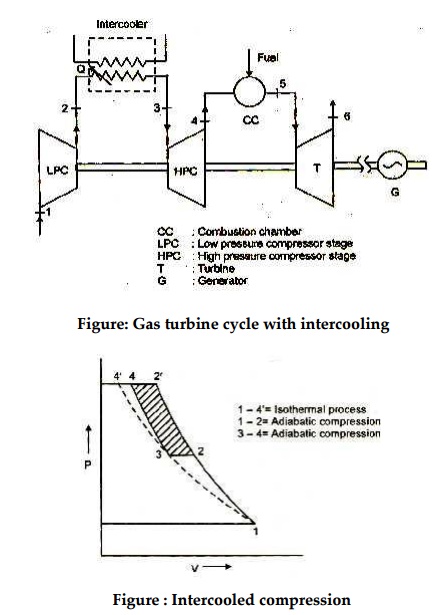

Thermodynamic processes involved in multistage inter cooled compression are shown in figure. First stage compression occurs in low pressure compressor (LPC) and compressed air leaving LPC at ‘2’issent to intercooler where temperature of compressed air is lowered down to state 3 at constant pressure. In case of perfect intercooling the temperature after intercooling is brought down to ambient temperature i.e., temperature at 3 and 1 are same. Intercooler is a kind of heat exchanger where heat is picked up from high temperature compressed air. The amount of compression work saved due to intercooling is obvious from p-V diagram and shown by area 2342’Area. 2342’givestheamount of work saved due to intercooling between compression.

Figure: Gas turbine cycle with intercooling

Figure : Intercooled compression

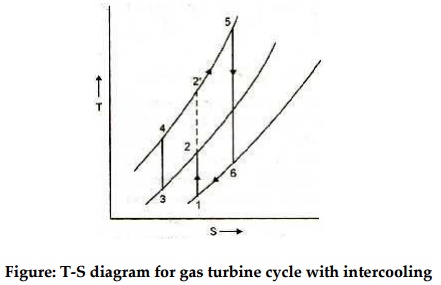

Some large compressors have several stages of compression with intercooling between stages. Use of multistage compression with intercooling in a gas turbine power plant increases the network produced because of reduction in compressor work. Inter cooled compression results in reduced temperature at the end of final compression. T-S diagram for gas turbine cycle with intercooling shows that in the absence of intercooling within same pressure limits the state at the end of compression would be 2’while with perfect intercooling this state is at 4 i.e., T2’> T4. The reduced temperature at compressor exits leads to additional heat requirement in combustion chamber i.e., more amount of fuel is to be burnt for attaining certain inlet temperature as compared to simple cycle without intercooling.

Figure: T-S diagram for gas turbine cycle with intercooling

Thus intercooled cycle thermal efficiency may not increase with intercooling because of simultaneous increase in heat addition requirement. The lower temperature at compressor exit enhances the potential for regeneration so when intercooling is used in conjunction with regeneration an appreciable increase in thermal efficiency can result.

Net work output in gas turbine cycle with intercooling;

Wnet, intercool = m{(h5 –h6) –(h4 –h3) –(h2 –h1)}

Wnet, intercool = m cp {(T5 –T6) –(T4 –T3) –(T2 –T1)}