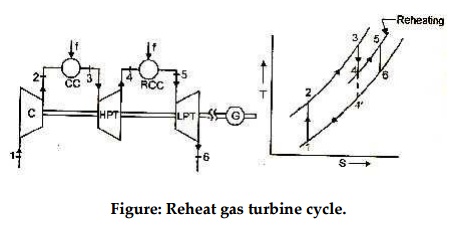

Gas turbine cycle with reheater

Reheat gas

C : Compressor

CC: Combustion chamber G : Generator

f : Fuel

HPT: High Pressure turbine LPT: Low pressure turbine

RCC: Reheat combustion chamber

Figure: Reheat gas turbine cycle.

Reheat gas turbine cycle arrangement is shown in figure. In order to maximize the work available from the simple gas turbine cycle one of the option is to increase enthalpy of fluid entering gas turbine and extend its expansion upto the lowest possible enthalpy value. This can also be said in terms of pressure and temperature values i.e., inject fluid at high pressure and temperature into gas turbine and expand upto lowest possible pressure value. Upper limit at inlet to turbine is limited by metallurgical limits while lower pressure is limited to near atmospheric pressure in case of open cycle. For further increasing in net work output the positive work may be increased by using multistage expansion with reheating in between. In multistage expansion is divided into parts and after part expansion working fluid may be reheated for getting larger positive work in left out expansion. For reheating another combustion chamber may be used.

Here in the arrangement shown ambient air enters compressor and compressed air at high pressure leaves at 2. Compressed air is injected into combustion chamber for increasing its temperature upto desired turbine inlet temperature at state3. High pressure and high temperature fluid enters high pressure turbine (HPT) for first phase of expansion and expanded gases leaving at 4 are sent to reheat combustion chamber (reheater) for being further heated. Thus reheating is a kind of energizing the working fluid. Assuming perfect reheating (in which temperature after reheat is same as temperature attained in first combustion chamber), the fluid leaves at state 5 and enters low pressure turbine (LPT) for remaining expansion upto desired pressure value. Generally temperature after reheating at state 5, is less than temperature at state 3. In the absence of reheating the expansion process within similar pressure limits goes upto state 4’.Thus reheating offers an obvious advantage of work output increase since constant pressure lines T-S diagram diverge slightly with increasing entropy, the total work of the two stage turbine is greater that that of single expansion from state 3 to state 4’,i.e.(T –T ) + (T –T ) > (T –T ’).

Here it may be noted that the heat addition also increases because of additional heat supplied for reheating. Therefore, despite the increase in network due to reheating the cycle thermal efficiency would not necessarily increases. Let us now carry out air standard cycle analysis.

Network output in reheat cycle, W net, reheat = WHPT + WLPT - WC

WHPT = m (h3 –h4), WLPT = m(h5 –h6), WC = m(h2 –h1)

W net, reheat = m {(h3 –h4) + (h5 –h6) –(h2 –h1)}

W net , reheat = m cp {(T3 –T4) + (T5 –T6) –(T2 - T1)}

Assuming, T3 = T5

W net, reheat = m cp {(2T3 –T4) –T6 –(T2 –T1)}

Qin = m cp {(T3 –T2) + (T5 –T4)

W

h =

reheat

Qin