Ferrodynamic Wattmeters

Ferrodynamic Wattmeters

The operating torque can be considerably increased by using iron cores for the coils.

Ferrodynamic wattmeters employ cores of low loss iron so that there is a large increase in the flux density and consequently an increase in operating torque with little loss in accuracy.

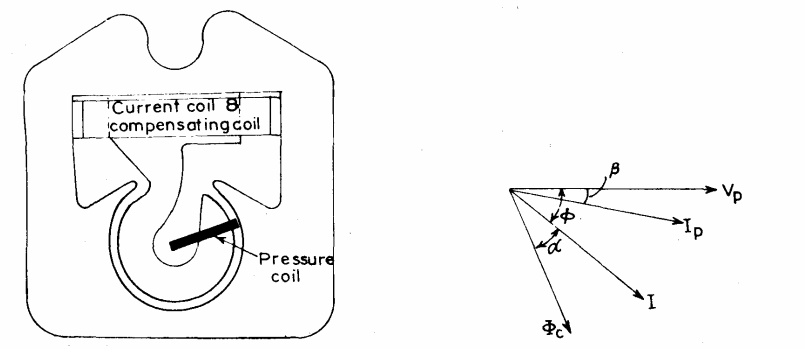

The fixed coil is wound on a laminated core having pole pieces designed to give a uniform radial field throughout the air gap.

The moving coil is asymmetrically pivoted and is placed over a hook shaped pole piece.

This type of construction permits the use of a long scale up to about 270° and gives a deflecting torque which is almost proportional to the average power. With this construction there is a tendency on the part of the pressure coil to creep (move further on the hook) when only the pressure coil is energized.

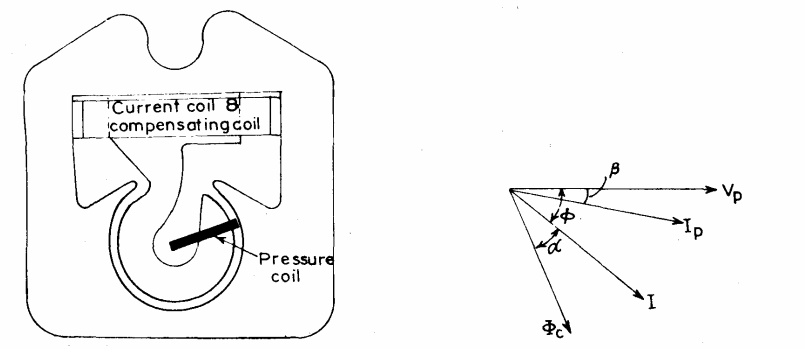

This is due to the fact that a coil tries to take up a position where it links with maximum flux. The creep causes errors and a compensating coil is put to compensate for this voltage creep.

The use of ferromagnetic core makes it possible to employ a robust construction for the moving element.

Also the Instrument is less sensitive to external magnetic fields. On the other hand, this construction introduces non-linearity of magnetization curve and introduction of large eddy current & hysteresis losses in the core.